1.Universal einsetzbar zum Mischen von pulverförmigen, körnigen, flockigen, klumpigen und viskosen Materialien in Branchen wie Futtermittelproduktion, Lebensmittelverarbeitung, chemische Industrie, Pharmazie und Pestizidherstellung.

2.Nettomischzeit ≤ 120 Sekunden,

3.Mischgleichmäßigkeit ≥ 95 %,

4.Rückstandrate ≤ 0,5 %,

5.Stromverbrauch pro Tonne Material ≤ 0,9 kWh/t

Merkmale:

1. Die W-förmige horizontale große Mischkammer erzeugt eine Schwerelosigkeitszone im Überlappungsbereich der beiden Rotoren. Dadurch werden die Materialien nach oben getragen und befinden sich kurzzeitig in einem gewichtslosen Zustand, wodurch eine allseitige kontinuierliche Zirkulation und eine ineinandergreifende Scherwirkung ermöglicht wird. Dies gewährleistet ein schnelles und gleichmäßiges Mischen.

2. Die Doppelschnecken-Mischstruktur gewährleistet eine hohe Mischeffizienz und Homogenität.

3. Die vollständige große Auslassöffnung ermöglicht eine schnelle Entleerung mit minimalem Rückstand.

4. Der Abstand zwischen dem Hauptrührwerk und dem Zylinder ist gering, wodurch im Mischzylinder nur geringe Restmengen verbleiben.

5. Mit einem Rückluftkanal mit großer Querschnittsfläche ausgestattet, um die Druckdifferenz zwischen oberer und unterer Kammer auszugleichen und somit das Austreten von Staub zu reduzieren.

6. Die kombinierte Wellendichtstruktur mit mehreren Dichtelementen und Luftkammern gewährleistet eine vollständig dichte Welle.

7. Mit mehreren Flüssigkeitszuleitungen ausgestattet, zur bequemen Zugabe verschiedener Flüssigkeiten; die Flüssigkeitszugabekapazität beträgt bis zu 5 %, mit hervorragender Zerstäubungsleistung.

8. Mit einem Reinigungssystem aus komprimierter Luft ausgestattet, um eine Kreuzkontamination strikt zu verhindern.

9. Durch den Einsatz eines integrierten Schwerlastgetriebes wird eine höhere Übertragungseffizienz und ein gleichmäßigerer Betrieb erreicht.

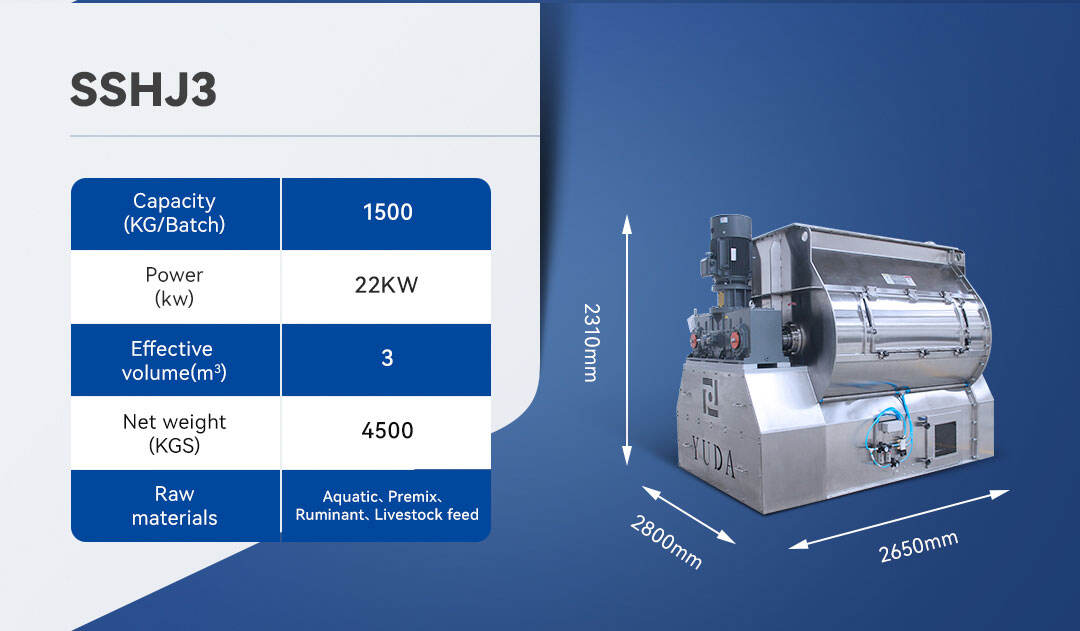

Modellinformationen:

| Modell | Effektives Volumen (m3) | Leistung (kw) | Kapazität (kg/Charge) | Abmessungen (mm) | Gewicht(kg) |

| SSHJ0.2 | 0.2 | 4 | 100 | 1600*1425*1150 | 1000 |

| SSHJ0.5 | 0.5 | 7.5 | 250 | 1800*2000*1500 | 1760 |

| SSHJ1 | 1 | 15 | 500 | 2000*2500*1400 | 2405 |

| SSHJ2 | 2 | 18.5 | 1000 | 2820*2345*2130 | 4320 |

| SSHJ3 | 3 | 22 | 1500 | 2650*2800*2310 | 4500 |

| SSHJ4 | 4 | 30 | 2000 | 2890*3070*2450 | 6260 |

| SSHJ6 | 6 | 37 | 3000 | 3530*2980*2460 | 7500 |

| SSHJ8 | 8 | 45 | 4000 | 3800*2980*2400 | 8500 |