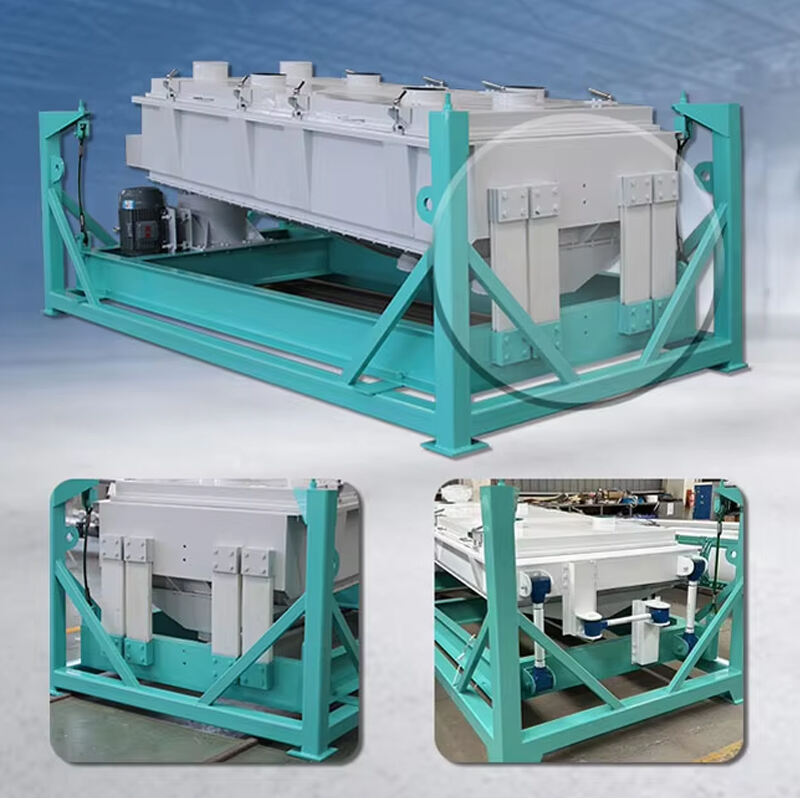

Pellet screeners Yuanyuda, yang termasuk dalam rangkaian peralatan pengolahan pakan, pupuk, dan forage perusahaan, merupakan produk baru yang dipromosikan untuk bisnis perdagangan luar negerinya. Yuanyuda memposisikan pellet screeners ini sebagai aksesori yang sangat penting dalam lini pengolahan pakan. Mesin pemisah ini mencerminkan komitmen perusahaan dalam meningkatkan kualitas dan konsistensi produk. Misi kami adalah menyediakan peralatan yang andal dan terjamin untuk semua proyek terkait pakan.

Memurnikan Pakan dengan Penghilangan Kotoran

Screener memurnikan pelet pakan dengan menghilangkan gulma dan kotoran seperti serbuk, pecahan, serta cangkang. Proses pemurnian ini merupakan langkah pra-perlakuan penting untuk menjamin kualitas pakan, serta melindungi kesehatan dan keselamatan hewan. Didukung oleh komitmen kualitas Yuanyuda, screener ini mampu menangkap partikel-partikel yang tidak diinginkan sebelum merusak produk akhir Anda—kemampuan yang tidak dimiliki banyak mesin lain yang kurang andal.

Memastikan Ukuran Pelet yang Konsisten demi Kualitas Pakan yang Andal

Screener pelet Yuanyuda mengklasifikasikan pelet berdasarkan ukuran, memisahkan pelet yang terlalu kecil atau terlalu besar dari pelet standar. Proses penyaringan ini juga menghilangkan variabilitas pada produk akhir, sehingga setiap batch pakan memiliki ukuran partikel yang persis sama. Tingkat konsistensi ini memungkinkan produsen pakan menyediakan produk yang stabil dan seragam ke pasar—dan begitulah cara kepercayaan terhadap kualitas pakan akhir terbentuk.

Operasi Mulus dengan Lini Produksi Penuh

Pemisah Pellet Yuanyuda kompatibel dengan peralatan lain dalam lini pengolahan pakan, seperti granulator, pendingin aliran berlawanan, dan sistem konveyor pneumatik. Alur produksi berjalan secara serasi, dengan setiap tahap saling mendukung—menghilangkan gangguan yang dapat mengurangi kualitas. Sebagai bagian dari solusi proyek pakan berkualitas tinggi perusahaan, pemisah ini mendukung seluruh proses produksi dari bahan baku hingga pelet jadi serta mengurangi masalah operasional yang disebabkan oleh ketidaksesuaian peralatan yang kesulitan menangani alur produksi semacam ini.

Penyesuaian terhadap berbagai jenis pakan untuk menjaga konsistensi kualitas

Jenis pakan yang berbeda memiliki persyaratan kualitas yang unik. Pemisah pelet Yuanyuda dapat secara efektif memenuhi persyaratan unik ini dan beroperasi secara andal dengan formula pakan apa pun. Pelet pakan akuatik berdensitas tinggi maupun pelet pakan unggas berdensitas rendah dapat disaring dan diklasifikasikan secara efisien dan akurat—karena kualitas merupakan prioritas utama dalam produksi pakan pelet, baik untuk hewan akuatik maupun unggas. Fleksibilitas ini memungkinkan perusahaan untuk menyesuaikan solusi bagi berbagai proyek pakan.

Secara singkat, peralatan penyaring pelet Yuanyuda dapat menghasilkan produk dengan kualitas lebih tinggi dan keseragaman yang lebih baik melalui penghilangan kotoran, distribusi ukuran partikel yang seragam, serta lini produksi yang sepenuhnya terintegrasi—sekaligus mampu menangani berbagai laju aliran pakan yang berbeda. Mesin-mesin ini tidak hanya memastikan kualitas pakan yang unggul, tetapi juga membantu produsen pakan ternak dan unggas mempertahankan standar produksi yang konsisten, sehingga menjadikan Yuanyuda sebagai pilihan utama Anda untuk peralatan pengolahan pakan berkualitas tinggi.

EN

EN