- Ana Sayfa

- Çözüm

- Ürünler

- Hakkımızda

- Performans Davası

- Haberler

- İletişim

Bu, Mink yuvarlak üretimi yapan makinelerdir. Büyük miktarda küçük, genellikle bir malzeme olan yuvarlak parçalar üretmek için kullanılan makineler. Bu yuvarlaklar farklı maddeler kullanılarak üretilir ve bu da onları birçok farklı alanda gerçekten faydalı hale getirir. Bu makineler, çeşitli görevlerin gerçekleştirilmesini değiştirdi, işin daha kolay ve daha kısa sürede tamamlanmasını sağladı. Bu makale, sahip olmanın önemi hakkında size harika bilgiler sunacak, işlere nasıl yardımcı olduktan, içerde ne olduğunu ve daha fazlasını — yuvarlak üretim makinesinde en iyi olan nedir? organik gübre pellet makinası s, nasıl işlere yardımcı olduklarını, içinde ne gibi bir yapıya sahip olduklarını ve daha fazlasını — yuvarlak üretim makinesinde en iyisi nedir?

Pelt üreten makineler gerçekten faydalıdır çünkü işletmelerin peltleri hızlı ve toplu olarak üretmesine yardımcı olabilir. Bu makineler, üretimini daha kolay hale getirir ve böyle bir ekipman olmadan, şirketler mali tablolarında yer alan peltleri üretmek için daha zor zamanlar yaşardı. Pelletler sadece evde kullanılmak üzere değil, evlerin ve binaların ısıtılması için de kullanılmaktadır. Ayrıca sobalar ve griller için de kullanılır ve çeşitli endüstrilerdeki bazı türlerde ekipmanlarda yer alır. Dolayısıyla pellet üretim makineleri, yaşamımızın çeşitli sektörlerinde enerji ve malzeme üretmek için hayati öneme sahiptir.

Üretimimizde pilav soğutucu s pelletleri daha hızlı ve kolay bir şekilde yapmak için önemli bir rol oynayacak. Bu makineler olmadan, insanlar pelletleri elle oluşturmak zorunda kalırdı, bu da çok uzun sürmesi ve aşırı derecede işgücüne bağlı olmasından dolayı problem yaratabilirdi. Şirketler pellet stoklarını korumakta zorluk çekebilirlerdi. Bu makineler, ahşap, plastik ve metal gibi tüm malzemelerden pellet üretmeyi mümkün kılar. Bu esneklik,理想的 herhangi bir malzemeyi kullanıma uygun hale getirir ve bu da bu makinelerin bugün neden bu kadar güçlü olduğunu gösterir.

Pellet üretim makinaları, birçok işletmecin tarafından çeşitli avantajları nedeniyle yaygın olarak kullanılmaktadır. En önemli avantaj, bu makinelerin şirketlere daha az zaman içinde ancak daha fazla miktarda pellet üretme imkanı sağlayışıdır. Üretkenlik arttıkça, şirketler müşteri ihtiyaçlarına daha hızlı yanıt verebilir. Pellet üretim makinelerini kullanmak aynı zamanda daha az işgücü gerektiği için para tasarrufu sağlar, daha az çalışan ile çalışılabilir. Bu da genellikle işletmelerin daha verimli bir şekilde çalışmasını ve iyi kâr etmesini sağlar; her ikisi de başarılarının kritik unsurlarıdır.

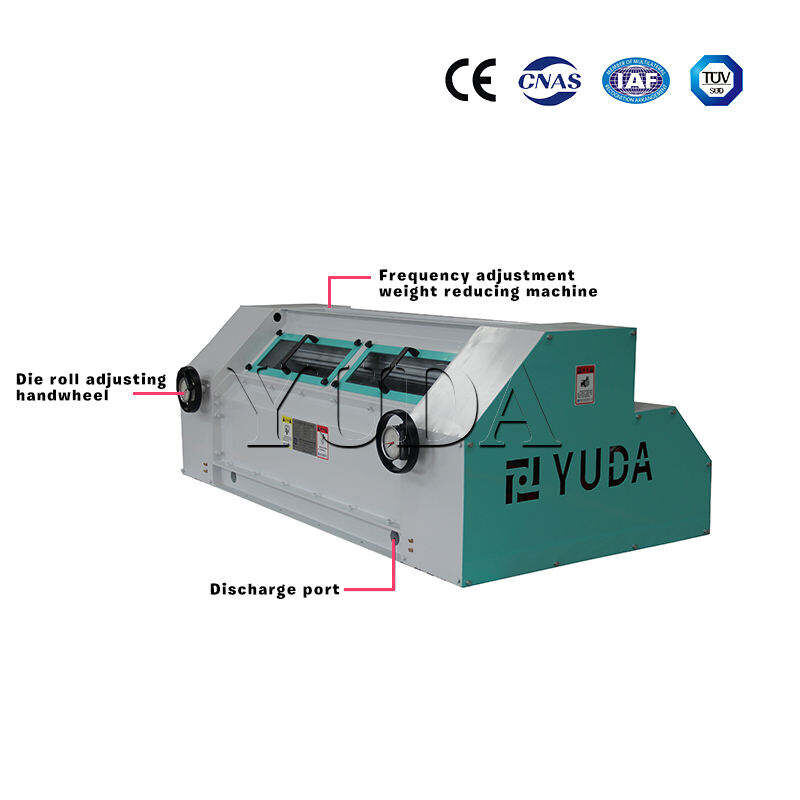

Paket üretim makinalarının iç işleyişine bakmak oldukça korkutucu olabilir. Ancak, aslında doğada basitler ve aynı şekilde basitçe çalışırlar. İlk olarak, ham madde depolandığı ve süreç buradan başladığı bilinen bir hopper alanı vardır. Oradan bu maddeler, bildiğimiz ve/veya sevdiğimiz küçük çaplı paketlere ezildikleri bir kalıba aktarılır. Paketler oluşturulduktan sonra, soğumaları gerekecektir. Soğuduktan sonra ambalaj edilir ve farklı şekillerde satılmaya veya kullanılma için hazır hale gelirler. Bu makinaların nasıl işlediklerini bilmekle beraber, bu paket üretim teknolojisinin arkasındaki bilgiyi sevebiliriz.

Kaliteli bir pelet üretim makinesi ararken dikkate almanız gereken birkaç özellik vardır. İlk olarak, makinenin kapasitesini belirlemeniz gerekir çünkü bu, belirli bir anda makineye yüklenebilecek malzeme miktarını gösterir. Bu, kısa sürelerde büyük hacimde pelet üretmek zorunda olan işletmeler için temel bir özelliktir. Daha sonra, Kolay Kullanıma Ve Bakıma Sahip Bir Makine Arayın. Böylece uzun vadede zaman ve para tasarrufu sağlayabilirsiniz, çünkü işçiler makineyi daha kolay kullanabileceklerdir. Nihayetinde, makinenin yüksek kaliteli bileşenlerden yapılmış olduğundan emin olmalısınız. Üretim kuruluşlarının son istedikleri şey, çıktıya ve kaliteye zarar veren makineyle ilgili bir sorun yaşarmaktır, bu nedenle güvenilir bileşenlerden oluşan bir makineyi birleştirmek faydalıdır — sonuçta, bu, yıllarca hizmet verecek bir şeydir.

Şirketimizin pelet üretim makinesi, prestijli uluslararası ISO9001:2015 Kalite Yönetim Sistemi belgesine sahiptir. Kalite denetimi konusunda özelleşmiş bir ekip bulunmaktadır. Yüksek düzeyde eğitilmiş denetçilerimizden oluşan ekibimiz, tesisimizden çıkan tüm ürünlerin en yüksek performans ve çevre uyumluluğu standartlarına uygun olmasını sağlar. Testlerimiz arasında performans testleri, dayanıklılık testleri ve güvenlik kontrolleri yer alır. Kalite denetimi prosedürleri titiz ve kapsamlıdır.

Pellet üretim makinesi 34.500 metrekarelik bir alanı kaplar ve en üst düzey teknolojiye sahip tam donanımlı CNC lazer kesim makineleri, otomatik profil kumlama makineleri, otomatik kaynak makineleri, büyük ölçekli kesme ve bükme makineleri, CNC tornalar vb. cihazları içerir. Tam teslim edilebilir (turnkey) yem fabrikası projeleri; tesis planlamasını, üretim ve tasarım kurulumlarını, devreye alma işlemlerini ve personel eğitimi dahil olmak üzere çeşitli tiplerde ve boyutlarda tamamlanmıştır.

Kendi ürünlerimizden 90 adet pellet üretim makinesi üretiyoruz. Bu durum, maliyetleri yerinde kontrol etmemizi sağlar. Yem makineleri ve ekipmanlarının üretiminde 20 yılı aşkın tecrübemiz bulunmaktadır; ürünlerimiz Rusya, Fransa, Malezya, Güney Kore, Kanada, Mısır, Avustralya ve diğer 60’tan fazla ülkeye ihracat edilmektedir. Ayrıca kullanıcıya ürün satışına yönelik mükemmel teknik destek sağlamaktan, teknik eğitim hizmetlerinden ve bakım servis ağına kadar kapsamlı destek veriyoruz.

pelet üretim makinesi için ERP ve OA sistem yönetim yazılımı; kuruluşun yönetim yeteneklerini geliştirmek ve ofis işlemlerini otomatikleştirmek amacıyla kullanılır. Ayrıca hızlı gelişme çıktılarına ulaşılmasına da yardımcı olur.