Xususiyatlari:

1.Ikki qavatli loparli tuzilishga ega. Tez hamda tekis aralashtirish.

2.To'liq uzun ochiluvchi chiqish tuzilishini qabul qilish aralashmalar tez chiqarilishini va qoldiq moddalarning minimal darajasini kafolatlaydi.

3.Asosiy lopar bilan silindr o'rtasidagi bo'shliq juda maydaroq bo'lib, aralashtiruvchi silindrda qolgan moddalarning minimal darajasini ta'minlaydi.

4.Katta kesimli qaytish havo kanaliga ega bo'lib, yuqori va quyi kameraning bosim farqini muvozanatlash uchun, shu bilan birga changning tashxisi darajasini kamaytiradi.

5.Bir nechta sig'imi elementlari va havo kamerasi bilan birlashtirilgan valning havo sig'imi tuzilishini qabul qilish valning o'qida hech qanday quyilishni oldini oladi.

6.Bir nechta suyuqlik qo'shish liniyalari bilan jihozlangan bo'lib, turli xil suyuqliklarni qo'shishni qulaylashtiradi, suyuqlik qo'shish hajmi esa 5% gacha yetib boradi va yuqori darajada atomizatsiya qilish xususiyatiga ega.

7.Qattiq havo bilan tozalash tizimi bilan jihozlangan bo'lib, chiqishlar orasidagi kesishishni qat'iy ravishda oldini oladi.

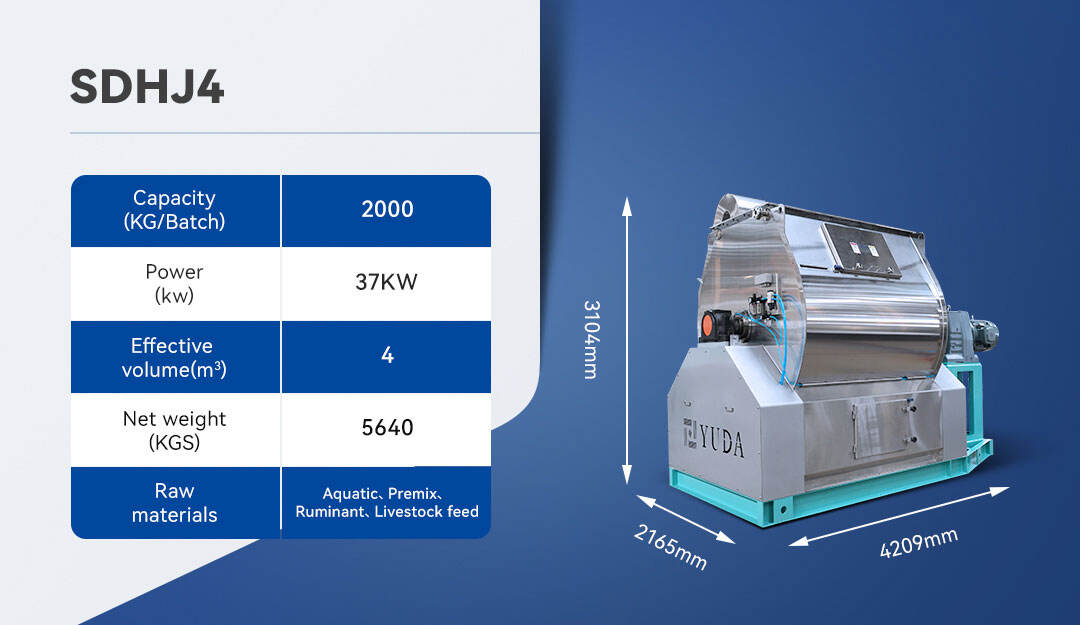

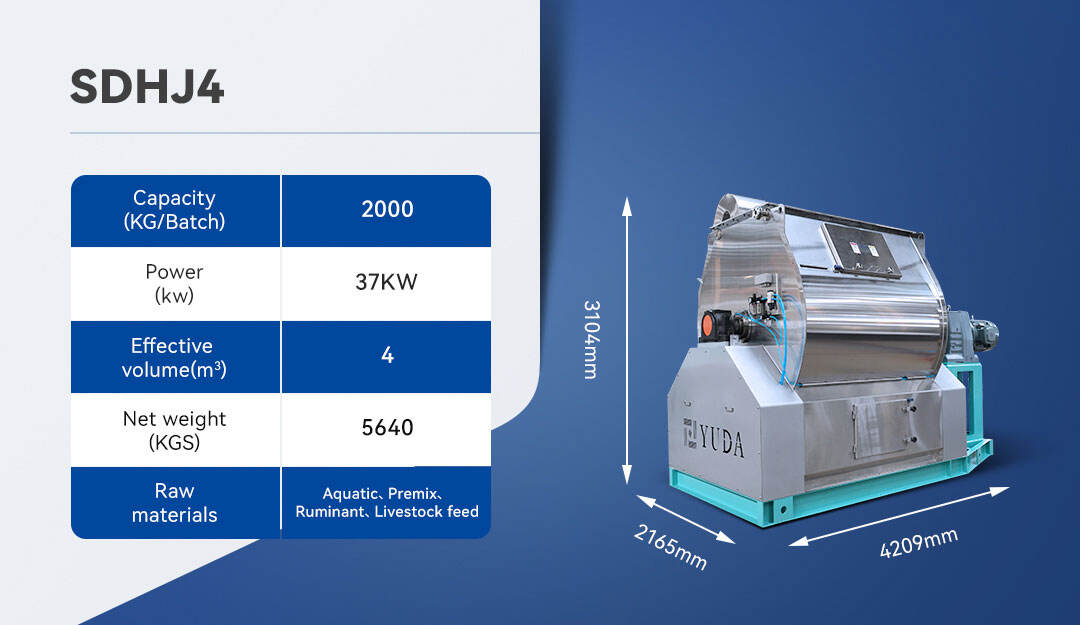

Model ma'lumotlari:

| Model |

Faol hajm (m3) |

Quvvat (KVt) |

Sig'imi (KG/Partiya) |

Olchamlari (mm) |

Vazn(kg) |

| SDHJ0.2 |

0.2 |

2.2 |

100 |

1926*914*1244 |

850 |

| SDHJ0.5 |

0.5 |

7.5 |

250 |

2454*1168*1684 |

1245 |

| SDHJ1 |

1 |

15 |

500 |

2842*1362*1833 |

1900 |

| SDHJ2 |

2 |

22 |

1000 |

3324*1734*2200 |

2830 |

| SDHJ4 |

4 |

37 |

2000 |

4209*2165*3104 |

5640 |

EN

EN