آلات Hammermill هي آلات خاصة تساعد في صنع الورق. تلعب هذه الآلات دورًا رئيسيًا في القطاعات التجارية ذات الطلب العالي على الورق. لذا، استمر في القراءة لاكتشاف كيفية عمل آلات Hammermill وما هو القيمة التي تقدمها.

الماكينات المطحنة هي أجهزة تكسر وتدقق أي مواد يتم إدخالها إليها. تحتوي على مطارق تضرب المواد بشكل متكرر للغاية حتى تصبح دقيقة جدًا. ثم يتم معالجة الشreds إلى ورق. وهي أيضًا سريعة جدًا، مما يسمح للشركات بإنتاج كميات كبيرة من الورق بسرعة باستخدام عملية الماكينة المطحنة.

تستخدم الشركات كميات كبيرة من الورق للكتابة والرسم والطباعة وما إلى ذلك. تجعل Hammermills الأمر أسهل وأسرع للشركات لإنتاج الورق. بعض الشركات تنتظر وقتًا طويلاً للحصول على الورق الذي تحتاجه، ولكن باستخدام Hammermills، يمكنهم الاستمرار في الحصول عليه.

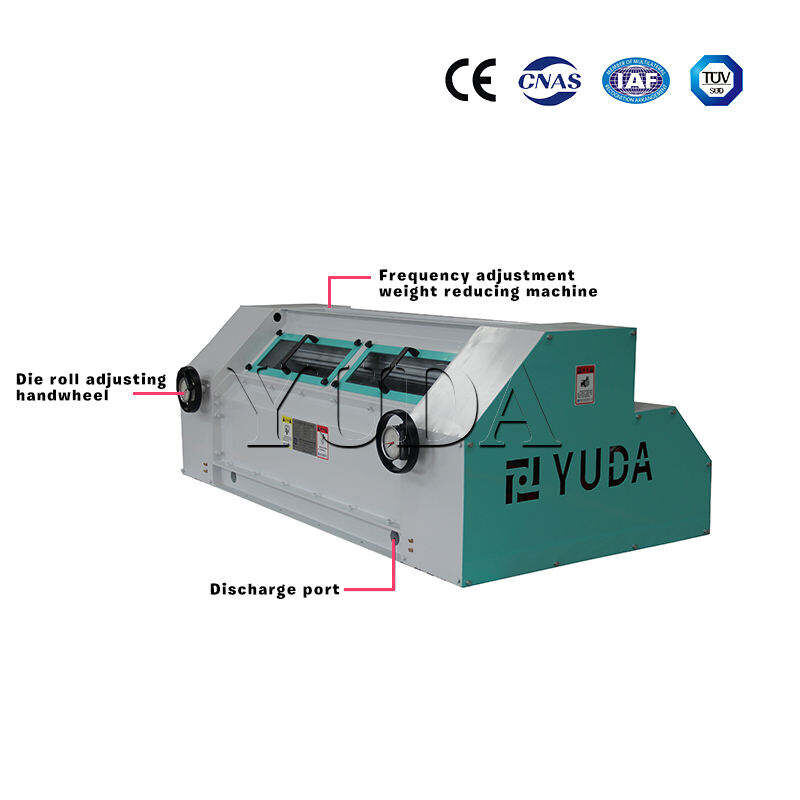

Hammermills المنتجات تم تحسينها على مر السنين لأغراض إنتاج الورق. تم تجهيزها بتقنيات جديدة حتى تعمل بشكل أسرع وأكثر كفاءة. قامت شركات مثل شنغهاي يوان يو دا بتحسين Hammermills لتمكين الشركات من إنتاج ورق عالي الجودة في وقت أقل.

تبدأ مواد Hammermill بالعناصر الأساسية مثل الخشب أو الورق المعاد تدويره. تقوم Hammermill بسحق هذه المواد إلى قطع صغيرة. يتم خلط هذه القطع مع الماء وغيرها من المواد لإنشاء مزيج سائل. ثم يتم نشر هذا المزيج وتجفيفه لتشكيل الورق.

Hammermills آلة حبيبات العلف استخدمها العديد على مر السنين لمساعدة في عملية صنع الورق. توفر للشركات الوقت والمال عن طريق صنع الورق بسرعة. وباستخدام المواد المعاد تدويرها، تسمح Hammermills للشركات بإنتاج نفايات أقل. كما أنها تنتج ورقًا عالي الجودة يكون ناعمًا ولديه شعور جيد أثناء الكتابة.

نُصنِّع ٩٠٪ من منتجاتنا بأنفسنا. وهذا يسمح لنا بالتحكم في تكاليف آلات التقطيع الورقية (Hammermill) عند نقطة الإنتاج. ولدينا خبرة تزيد على ٢٠ عامًا في إنتاج معدات وآلات ومستلزمات تغذية الحيوانات، والتي نصدِّرها إلى روسيا وفرنسا وماليزيا وكوريا الجنوبية وكندا ومصر وأستراليا وغيرها من أكثر من ٦٠ دولة. كما نقدِّم للمستخدمين الدعم في إنشاء شبكة مثالية للاستشارات الفنية وبيع المنتجات والتدريب الفني وخدمات الصيانة.

نستخدم برامج إدارة أنظمة تخطيط موارد المؤسسة (ERP) وأنظمة إدارة آلات التقطيع الورقية (Hammermill) لتعزيز الإدارة الحديثة للشركة وأتمتة المكاتب. وسيساعدك ذلك في تحقيق إنتاجٍ سريعٍ يدعم عملية التطوير.

الشركة هامرميل حصلت على شهادة نظام إدارة الجودة الدولي المرموقة ISO9001:2015. ولدينا فريق مُخصص لفحص الجودة. وسيضمن فريق المفتشين المدربين تدريباً عالياً لدينا أن جميع المنتجات الخارجة من منشآتنا تتوافق مع أعلى معايير الأداء والامتثال البيئي. وتشمل اختباراتنا تقييمات الأداء، واختبارات المتانة، وكذلك فحوصات السلامة. وإجراءات فحص الجودة صارمة وشاملة.

تغطي شركة هامرميل مساحة قدرها ٣٤٬٥٠٠ متر مربع، وقد أدخلت مجموعة كاملة من أحدث آلات القطع بالليزر باستخدام الحاسوب (CNC)، وآلات الرملي الآلية للإطارات، وآلات اللحام الآلية، وآلات القص والثني والقص على نطاق واسع، ومخارط الـ CNC وغيرها. وتشمل مشاريع التغذية الجاهزة (Turnkey) الكاملة أنواعاً وأحجاماً مختلفة تشمل تخطيط المنشآت، والتصنيع، والتصميم، والتركيب، والتشغيل التجريبي، وتدريب الكوادر.