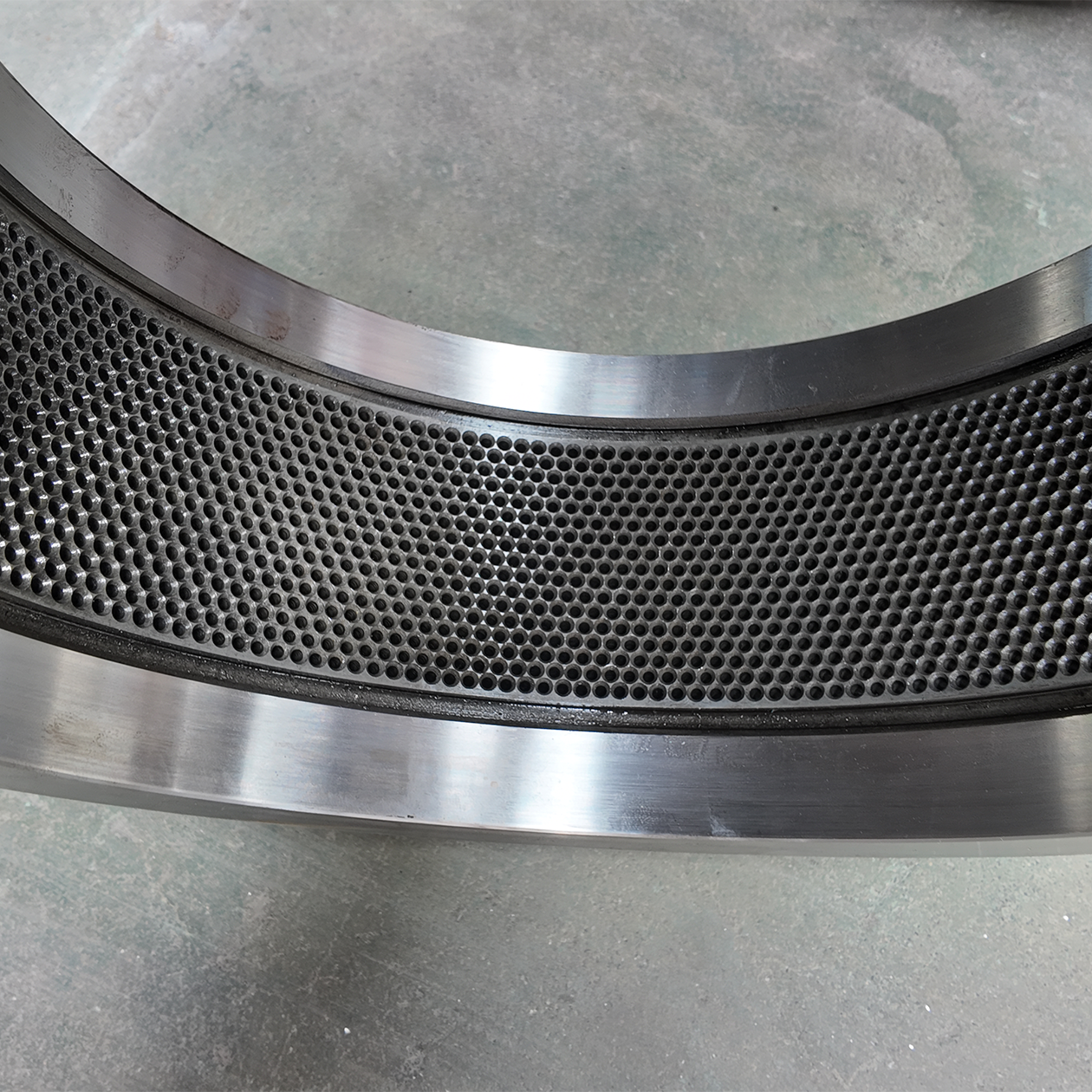

اليوم، نحن نتحدث عن قالب حلقة مطحنة الحبيبات، وفي الوقت نفسه، نحن أيضًا نوضح أهمية قالب الحلقة في صنع الحبيبات، مثل طعام الحيوانات والوقود. فهو مهم لأنه مكون حاسم من آلة مطحنة الحبيبات. يساعد في تشكيل وضغط المواد إلى حبيبات صغيرة. في هذا السياق،他是一个 كالقالب للمنتج النهائي.

في هذه المقالة، سنناقش فوائد استخدام قالب حلقي جيد عند إنتاج الحبيبات، وكيف أن له عدة مزايا. تعمل ماكينات حبيبات ذات جودة عالية بشكل أفضل. وهذا يعني أنها يمكن أن تنتج المزيد من الحبيبات بجودة أعلى. مع مرور الوقت، يمكنها أيضًا تقليل تكاليف الصيانة والاستبدال، مما يؤدي إلى توفير الوقت والتكاليف.

يجب أخذ العوامل مثل المادة التي تعمل عليها، حجم الحبيبات وطاقة الإنتاج للآلة في الاعتبار عند اختيار قالب حلقي لمطحنة الحبيبات. لتسهيل هذا، يتم استخدام إعداد القوالب الحلقيّة الجديدة لأغراض متنوعة، وهو السبب في أن اختيار القالب المناسب مهم لتحقيق الأداء العالي.

الصيانة الدورية بالإضافة إلى استبدال القالب الحلقي عند الحاجة ضروريان للحفاظ على عمل مطحنة الحبيبات بكفاءة. مع الاستخدام المكثف، يتأثر القالب الحلقي بال摩损 تدريجيًا، مما قد يؤدي إلى انخفاض جودة الحبيبات المنتجة. الحفاظ على نظافة القالب الحلقي وتوفيقه بدقة يمكن أن يمدد من عمر القالب ويُنتج حبيبات ذات جودة عالية.

يُستخدم قالب القالب لإنتاج حبيبات موحدة بنسبة 100%. المنتجات هذا يساعد في تنظيم حجم وكثافة الحبيبات، معدات التشكيل ضمانًا لأن تكون جميعها متشابهة في الشكل والملمس. يمكن للقالب الحلقي المحافظ عليه جيدًا إنتاج حبيبات تتوافق مع المعايير المطلوبة لتكون صالحة كغذاء للحيوانات أو وقود بيولوجي.

نُصنّع ٩٠٪ من منتجاتنا بأنفسنا. وهذا يسمح لنا بالتحكم في تكاليف قالب الحلقة لمطحنة الكريات عند نقطة الإنتاج. ولدينا خبرة تزيد على ٢٠ عامًا في إنتاج آلات ومعدات ومستلزمات التغذية، والتي صدّرناها إلى روسيا وفرنسا وماليزيا وكوريا الجنوبية وكندا ومصر وأستراليا وغيرها من أكثر من ٦٠ دولة. كما نقدّم للمستخدمين شبكة متكاملة تشمل الاستشارات الفنية المثلى، وبيع المنتجات، والتدريب الفني، وخدمات الصيانة.

فازت الشركة بشهادة نظام إدارة الجودة ISO9001:2015 الخاصة بمُكَوِّنات مطحنة الكريات الحلقيّة. ولدينا قسم فحص عالي الجودة، وتلتزم فرق المفتشين المُدرَّبة تدريباً عالياً لدينا بضمان أن يتوافق كل منتج يخرج من منشآتنا مع أعلى معايير الامتثال البيئي والأداء. وتشمل اختباراتنا تقييمات الأداء واختبارات المتانة وفحوصات السلامة. كما أن إجراءات فحص الجودة صارمةٌ وشاملةٌ.

تغطي مُكَوِّنات مطحنة الكريات الحلقيّة مساحةً تبلغ ٣٤٥٠٠ مترًا مربعًا، وقد أدخلت الشركة مجموعةً كاملةً من أحدث آلات القطع بالليزر باستخدام الحاسوب (CNC)، وآلات الرملي التلقائية للهياكل، وآلات اللحام التلقائية، وآلات القص والثني والقص على نطاق واسع، ومخارط CNC وغيرها. وتشمل مشاريع التغذية المُقدَّمة جاهزةً للتشغيل (Turnkey) جميع مراحل المشروع بدءاً من تخطيط المصنع وتصنيع المعدات وتصميمها وتركيبها، وانتهاءً بالتشغيل التجريبي وتدريب الكوادر العاملة، وهي متوفرة بأنواع وأحجام مختلفة.

استخدام برنامج تخطيط موارد المؤسسة (ERP) ونظام إدارة المكاتب الإلكترونية (OA) لإدارة قوالب الحلقات في مطحنة الكريات الخاصة بشركتك وأتمتة المكتب، مما يحقق إخراجًا سريعًا للتطوير.