- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

Biomass Pellets: An Awesome Way to Produce Renewable Energy! It’s using magic to turn old things, like leaves and food scraps, into clean energy that helps to power our homes and schools. Let's dive into the world of Shanghai Yuanyuda biomass pellet machine, and how Shanghai Youanda is contributing to the greening of our planet!

Have you ever wondered what happens to all the plants and trees whenever they get old and fall? And, by using biomass pellet making, we will be able to gather these natural raw materials, such as wood debris, sawdust and garden waste, and convert them into small pellets that can be used as fuel. This is highly environmentally friendly, as not only does it eliminate garbage and waste from going into the landfills, but it also provides a clean source of energy.

By turning this organic waste into pellets of biomass energy that can replace fossils, we can turn it into good solutions and stop the rotten waste from making bad gases in the landfills. We can convert corn husks, straw, and leftover food into clean-burning pellets that make less pollution than normal fuels. This reduces our carbon footprint, demonstrating that we can be good stewards of our resource at the same time we do our part to protect the environment.

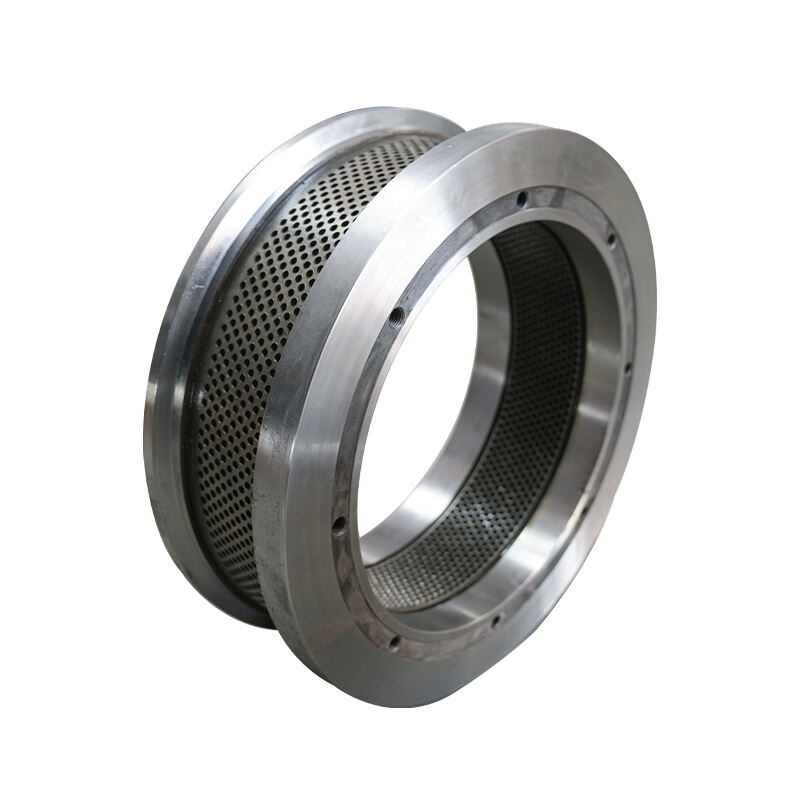

Nature is amazing! We use its power to produce clean energy with the help of biomass pellet production. Biomass pellets can be produced using natural components such as sunflower husks and peanut shells, which are safe and full of energy for burning. This Shanghai Yuanyuda biomass wood pellet machine allows us to partner with nature to provide clean fuel sources that are mutually supportive of us and the planet.

Imagine a future where our energy is sourced from renewables that don’t harm the planet. That’s the future we are striving to build with biomass pellets! These Shanghai Yuanyuda biomass pellet production line consist of organic materials that are infinitely renewable, which makes them a very good long-term fuel. Biomass pellets, for example, allow us to take a step away from relying on fossil fuels and toward a sustainable future for all of us.

As the demand for clean energy solutions grows, biomass pellets are revolutionizing the energy industry as a much more sustainable fuel alternative compared to conventional fuels. Companies such as Shanghai Yuanyuda are at the forefront of producing biomass pellets that are used to generate electricity, heat homes, and even power vehicles. This initiative not only opens up a whole new realm of employment opportunities for a multitude of individuals, but Shanghai Yuanyuda biomass pellet making machine also marks a significant turning point towards sustainable energy production.

The business covers an area of 34.500 square meters. The company is equipped with a range of high-tech CNC laser cutting machines. It also offers automatic welding machines, shearing benders, and large-scale machinery. Biomass pellet making are among other equipment. Undertake various types and scales of complete turnkey projects for feed, which includes complete plant planning, design production of equipment installation and commissioning as well as training for employees.

Using ERP and OA system management software to improve the company's modern management and automated Biomass pellet making. It will also help in achieving rapid development output.

The company has been awarded the Biomass pellet making ISO9001:2015 Quality Management System certification.We have a quality-control inspection department. Our team of highly trained inspectors is committed to ensuring that each product that leaves our facility meets the highest standards of environmental and performance compliance. Our tests include performance evaluations as well as durability tests and safety checks. Quality Inspection procedures are thorough and comprehensive.

We make 90 percent of our Biomass pellet making products. This lets us manage the cost at the location.We have more than 20 years of experience in manufacturing feed equipment and machinery. It is exported to Russia as well as more than 60 other countries like France, Malaysia and South Korea.