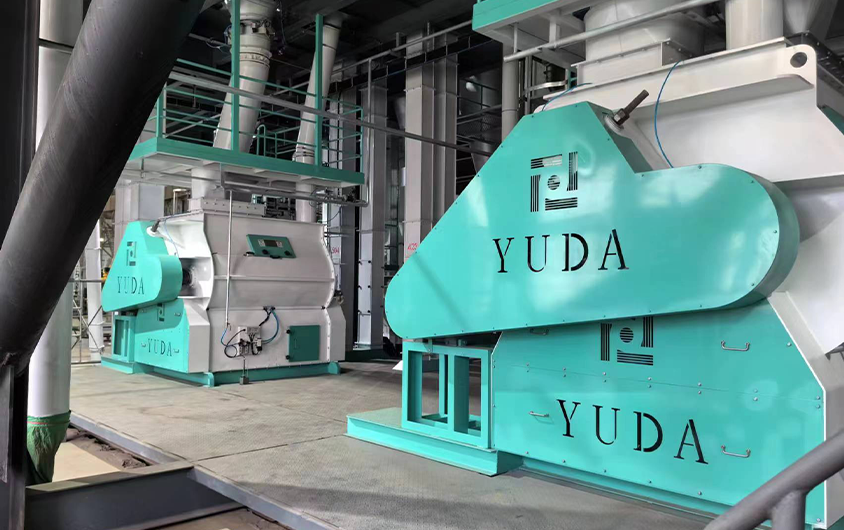

Cleaning

Effectively separate large impurities such as straw, stones, hemp pieces, paper pieces, clumps, plastic pieces, etc., so that materials can smoothly pass through other equipment, effectively ensuring the normal operation of subsequent processing equipment and conveying equipment.