Advanced cooling technology is needed in the production of high quality, durable and safe animal feed. A key component in this process is counterflow pellet coolers, which utilize an advanced process where the cool air flows through a moving bed of h...

VIEW MORE

The selection of a conveying system is highly significant to the industrial processes because efficiency, product integrity, and cost-effectiveness are directly influenced by the choice of conveying system. We (Shanghai Yuanyuda International Trade C...

VIEW MORE

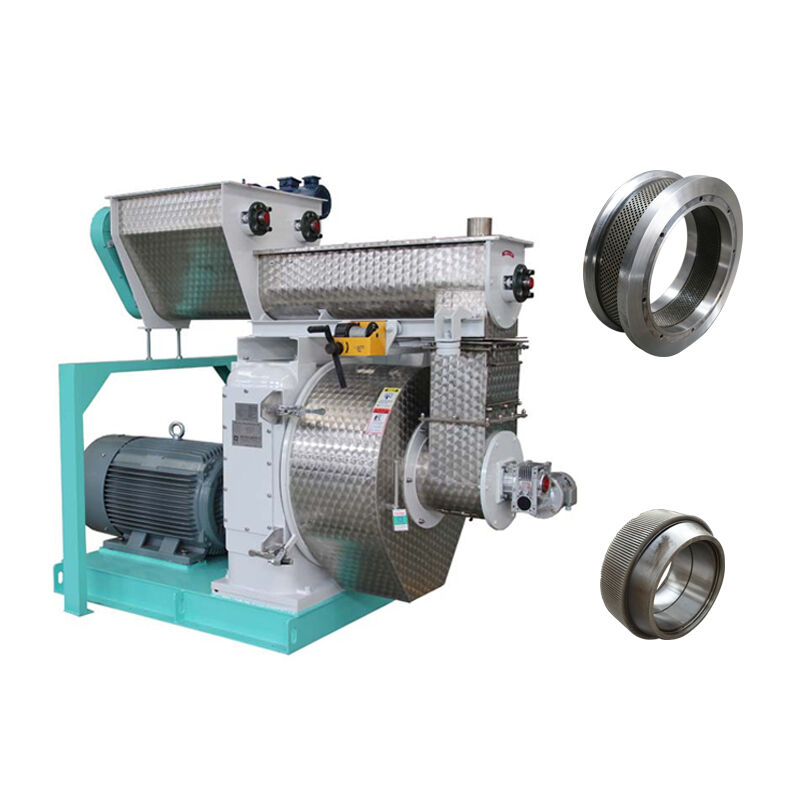

The Ring Die and Roller Shells are the most important wear parts of the pellet mill. Over wear causes reduced quality of the pellets, low production yield and increased energy costs. To profit maximally, biomass producers should do their utmost to co...

VIEW MORE

To the operators at feed mills, pellet breakage is not just a quality issue but also a direct loss of profit.Splintered pellets cause high fines, raw materials wastage, loss in nutritional uniformity and the quantity of dust in the plant. Although th...

VIEW MORE

The most important element in the final production of biomass pellets is the moisture content. It has a direct effect on the pellet density, strength, energy usage and the end product quality. When the raw material is excessively damp, the pellets ca...

VIEW MORE

A major challenge in industrial processing is to evenly mix powders and granules.The success of your entire production—from quality and consistency to output—depends on the mixer’s performance. For a company like Shanghai Yuanyuda I...

VIEW MORE

In industrial processing, the ability to handle a wide range of materials is crucial.A common question we often receive at Shanghai Yuanyuda International Trade Co., Ltd.is, "What kinds of materials can a Single Shaft Paddle Mixer mix effectively?" O...

VIEW MORE

In any industrial facility that handles powders, granules, or other dry materials, dust is more than an inconvenience; it is a major challenge.Dust can affect operations, the environment, and workers’ health.Controlling dust is critical for fac...

VIEW MORE

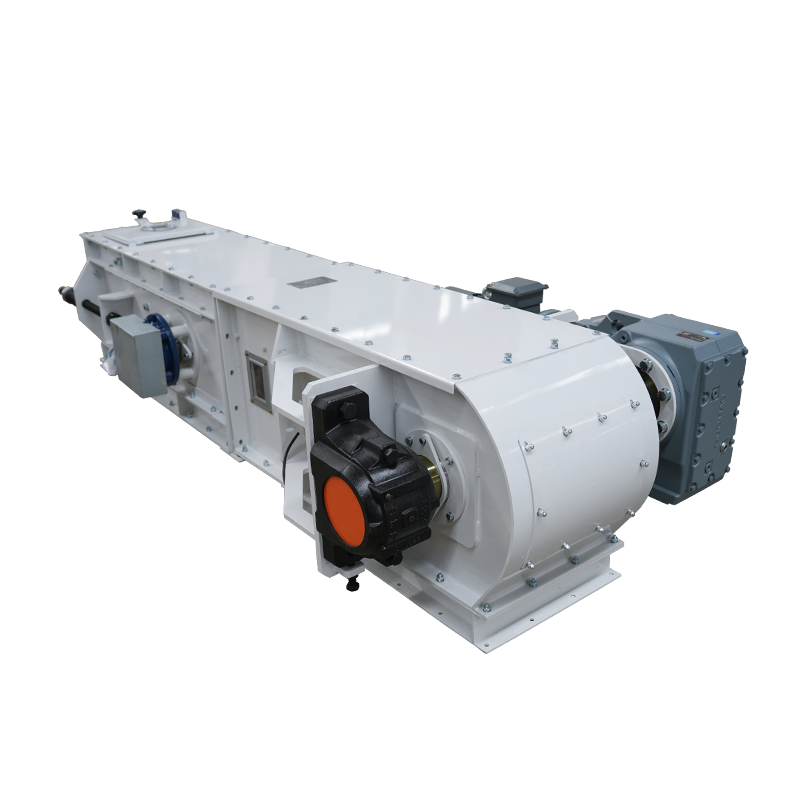

Chain conveyors are key machines that keep operations running to meet the growing demand for feed, fertilizer, and new-energy processing. They’re built robust to carry heavy loads, handle abrasive materials, and operate under heavy workloads. B...

VIEW MORE

A pulse-jet dust collector is a vital investment to keep the operations safe, efficient, and compliant for factories in the feed, fertilizer, and chemical industries. But, installing it is not the real solution as the performance can lower down becau...

VIEW MORE

The production of animal feed is a cutthroat industry that is concerned with efficiency and quality.Pellets require post-processing after the pelleting stage to control moisture and temperature, ensuring toughness, durability, and nutritional value d...

VIEW MORE

The cooling step after pelleting is one of the critical components defining the quality of a final product in modern feed production. Many types of coolers are available, but the preferred technology for an efficient feed mill has become the counterf...

VIEW MORE