In feed production lines, the hammer mill is a critical machine. It has a direct impact on grinding efficiency, product quality, and operating costs.Proper replacement of wear parts such as hammers and screens is necessary to maintain the equipment&r...

VIEW MORE

The screw conveyor, also known as an auger, is the unsung hero of many fertilizer and feed production plants. It is a reliable workhorse. However, like all systems, they are also prone to inefficiencies.which can cause greater energy costs, machine d...

VIEW MORE

As a leading manufacturer and supplier of complete feed machinery solutions, Shanghai Yuanyuda International Trade Co., Ltd. explains how counterflow cooling technology efficiently resolves these issues while maintaining optimal pellet quality. How C...

VIEW MORE

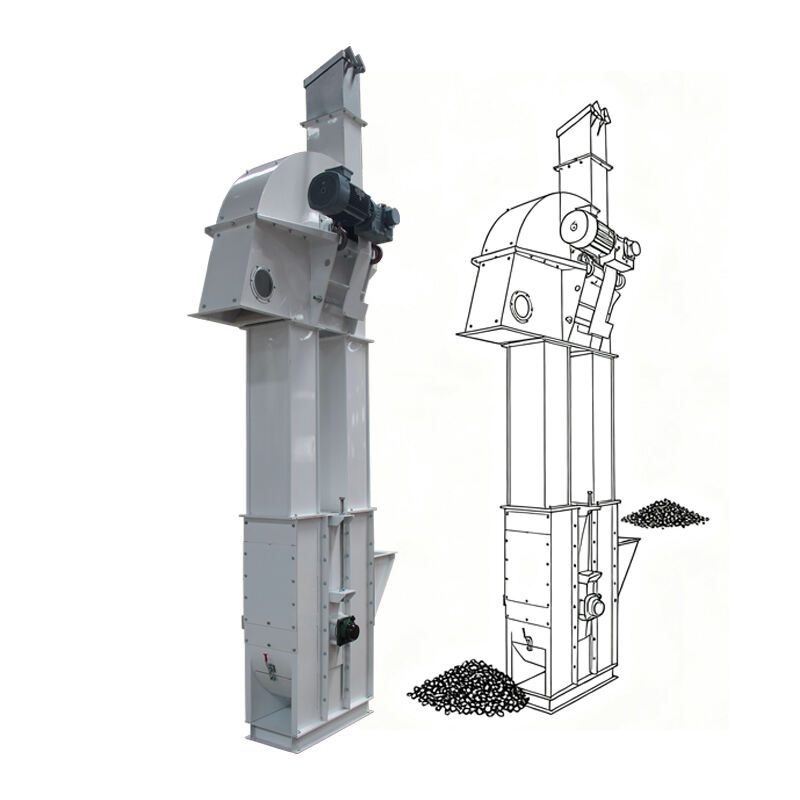

Yuanyuda offers bucket elevators for applications in the grain and feed processing industry. Backed by technical collaborations with top-tier institutions and certifications including ISO 9001 and CE, these conveyors address the key challenges in gra...

VIEW MORE

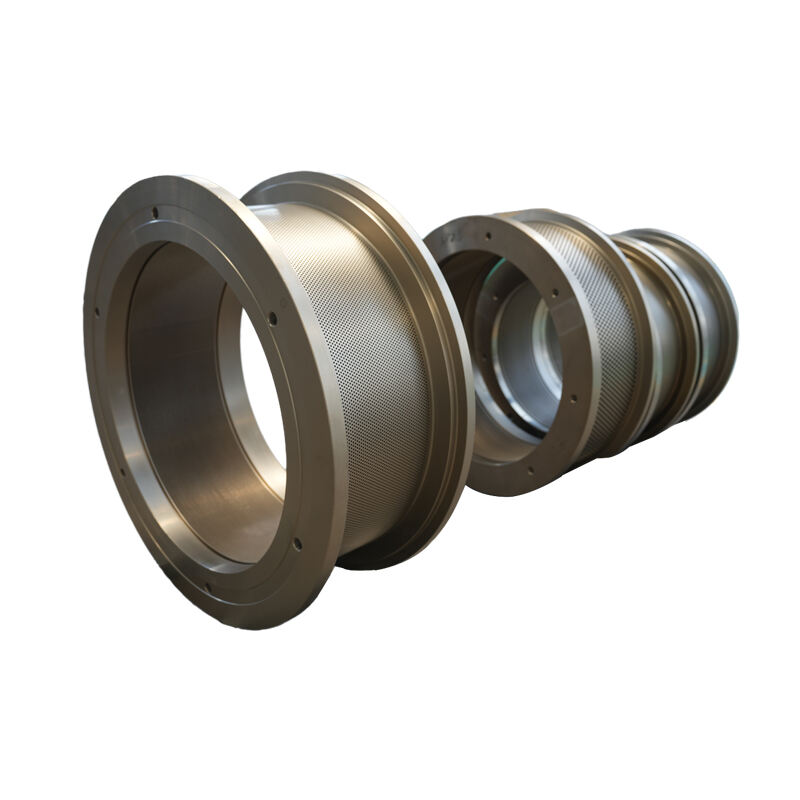

Yuanyuda is ready to be the backbone of innovative agriculture with durable feed pellet machines. Yuanyuda’s machines are designed to meet various farming demands and play a crucial role in both feed production and pet food manufacturing. Appli...

VIEW MORE

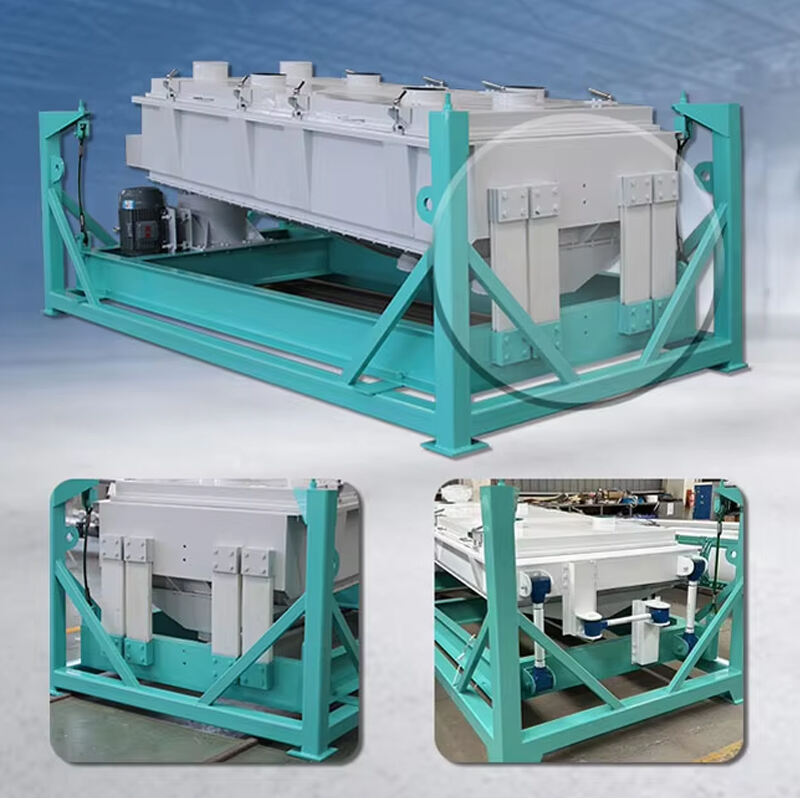

Yuanyuda’s pellet screeners, which belong to the company’s range of feed, fertilizer, and forage processing equipment, are newly promoted products for its foreign trade business. Yuanyuda positions these pellet screeners as indispensable ...

VIEW MORE

As a professional manufacturer of animal feed production lines, Yuanyuda is committed to developing technology to better increase your productivity and reduce processing costs with our machines. Equipped with advanced technology and a complete produc...

VIEW MORE

Yuanyuda Bucket Conveyor is applicable to conveying all kinds of granules, powder, small blocks and low-abrasive materials. Drawing on its 80 years of practical engineering experience and field-proven performance, Yuanyuda developed the conveyor with...

VIEW MORE

With the rapid development of animal husbandry and breeding industry, the demand for refinement and high efficiency of feed production is growing. As one of the key equipments for modern feed processing, grease spraying equipment is becoming an impor...

VIEW MORE

Screw feeders may jam with material, which leads to the disruption of feed production processes, downtime, and a reduction in the overall performance. The screw feeders of Yuanyuda are constructed in a way that such problems are reduced to a minimum....

VIEW MORE

The choice of a screw feeder is crucial to the efficiency and quality of material handling in feed plants. These factors directly influence the feed plant's operation and the quality of materials. Yuanyuda screw feeder is optimized based on a variety...

VIEW MORE

Centrifugal fans are neat machines; they make the air in large factories and buildings clean and fresh. Shanghai Yuanda produces these specialized machines, which are vital for retaining workers These places are safe and healthy. How Centrifugal Fans...

VIEW MORE