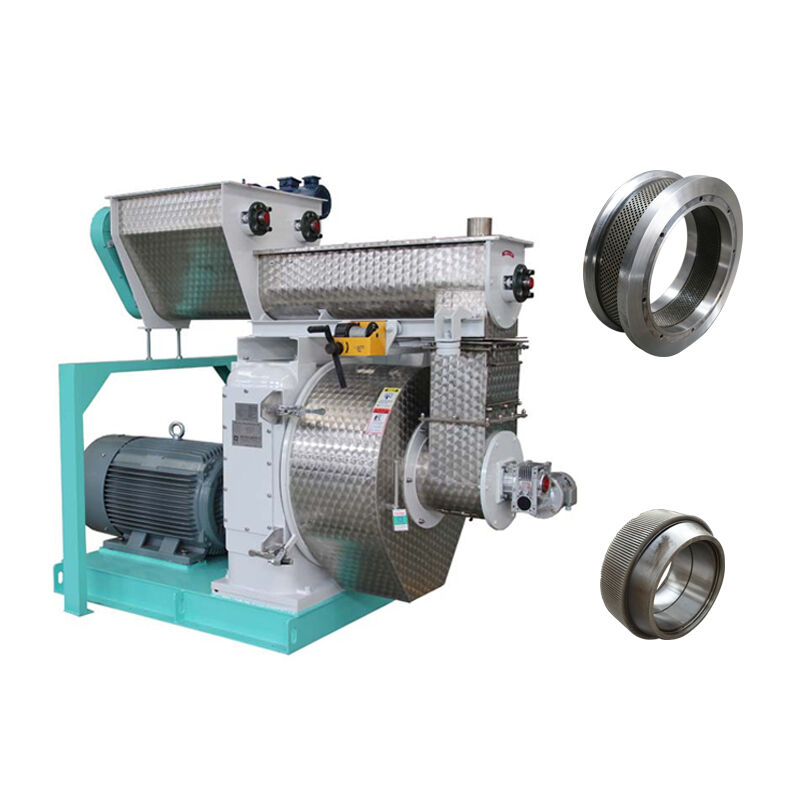

The Ring Die and Roller Shells are the most important wear parts of the pellet mill. Over wear causes reduced quality of the pellets, low production yield and increased energy costs. To profit maximally, biomass producers should do their utmost to control this wear. We not only offer high-performance granulating equipment and essential spare parts but also provide maintenance services to extend the service life of these components.Below are four key tips to reduce wear on pellet machine dies and rollers..

Prefer Raw Material Preparation and Conditioning

The long service life of these components is determined even before the material enters the pellet mill. Well-prepared feedstock is reliable, the initial barrier to wear. Make sure that your grinding equipment gives a homogeneous particle size. Fines assist in lubrication, whereas oversized particles generate uneven pressure and cause abrasive wear. Incorporate binders or additives into the mixing process to form a more pliable mixture.Above all, accurate steam conditioning is crucial to activate the lignin in the biomass.Fully conditioned material, i.e., optimum moisture and temperature, passes through the die holes with minimal resistance, thereby reducing the required extrusion force.This greatly reduces friction and abrasive wear of working surfaces of Ring Die and Roller Shells.

Choose the right Die and Roller Specifications

Dies and rollers are not identical. It is important to align their specifications to your feedstock. This is the choice of the best Ring Die hole diameter, compression ratio (length to diameter) and grade of material (e.g., high-chrome alloy). A compression ratio that is too high for softwood will cause undue friction, just as an excessively low ratio for hardwood will fail to produce long-lasting pellets. We have a high level of customization of both local and international models at Shanghai Yuanyuda. Our specialists can assist you in selecting or customizing the appropriate die (s) to ensure the desired quality of a pellet with the lowest wear. Equally, it is important to match your Roller Shells to the die to prevent unequal distribution of pressure.

Make sure that machines are assembled and maintained properly

It is necessary to have proper mechanical installations. Improper assembly or misalignment can also significantly accelerate wear. Make sure that the assembly with the Spindle and the Hollow Shaft is correctly adjusted and firmly held with high-strength clamps. The distance between the Roller Shells and Ring Die should be established and maintained in accordance with the manufacturer’s specifications—generally the same thickness as a business card.The gap that is too small results in metal-on-metal grinding while a too wide one results in pressure loss and roller slippage, and these elements cause more wear. Regular inspection of all press components—including bearings and drives—ensures the machine operates smoothly and avoids misalignment, which exerts destructive forces on the die and rollers. which conducts destructive forces to the die and rollers.

Adopt a Scientific Operation and Monitoring System

The stable operation is much less harmful to the wear parts than frequent starting, stopping and overloading. Maintain a steady flow of prepared material to the pellet mill using constant-volume conveying equipment. The machine should not be operated without feeding it with the prepared material, as it will lead to friction between the rollers and the die. Measure important parameters like amperage (load), pellet temperature and generation of fines. The excessive wear or feeding problem can be noticed by a sudden increase in power consumption or fines production. And, after pellets have been made, they are effectively hardened using quality cooling equipment and then separated by sifting equipment equipped with heavy-duty screen plates, and by so doing, the pellet mill is indirectly safeguarded, since the abrasive fines are separated before they can be reintroduced into the process.

EN

EN