- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

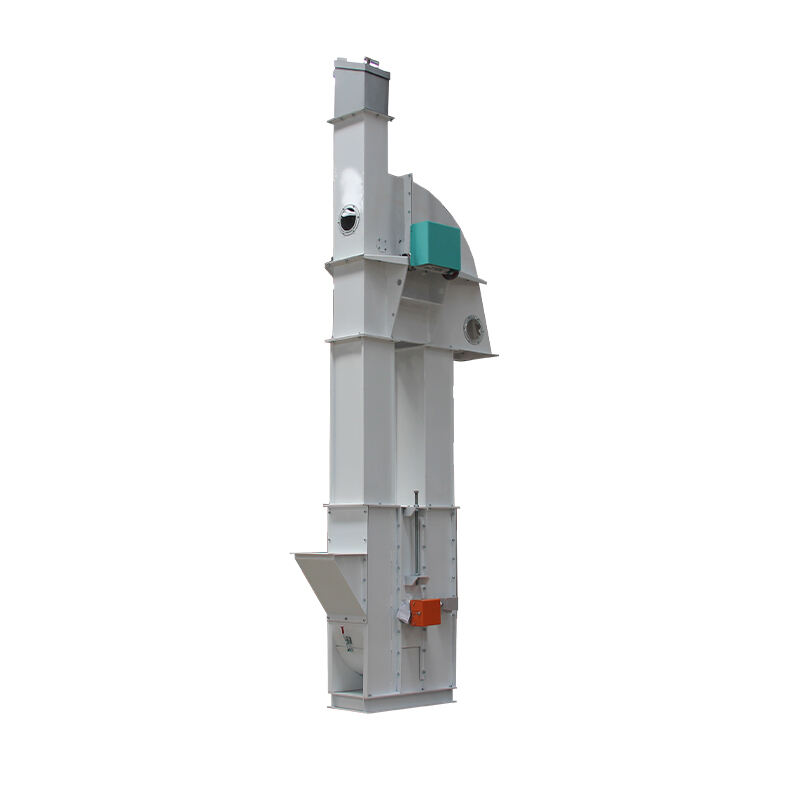

Conveying equipment is the machines that convey material from one location to another. That may not seem too thrilling, but a lot has changed in recent years thanks to new technology used in factories and beyond.

Novel technology in conveyor equipment makes the machines faster, safer and more adept at their jobs. It enables workers to complete their tasks faster and with a lower risk of injury. And there are stronger materials today that conveyor belts are made with. The feed grinder mixer are able to hold larger objects without breaking. This is especially critical in environments such as warehouses that need to move a lot of heavy loads all the time.

In factories, high-quality conveying equipment holds great importance. When the machines are disabled, that can lead to serious issues for all. This is why you must choose the right horizontal feed mixer for the job.

Selecting the right conveying equipment must consider the weights and distances and speeds of the products. Usually, different types of livestock feed mixer are more suitable for certain tasks, so make sure to check and see you are getting the right machine.

Modern Shanghai Yuanyuda conveying equipment has huge advantages. Provided they have the right machines, workers can move stuff around far faster and easier. What all this means is they can accomplish more work in less time, which is very beneficial to businesses looking to maximize productivity.

It is quite amazing the way conveying equipment is modifying the movement of materials. In the old days, moving heavy objects used to be a slow, exhausting and a dangerous chore. With animal feed mixer, it is as simple as pushing a button. This makes things safer for workers and helps everything move faster.

We have 90% of our own products, which allows us to manage costs from the source.We have over 20 years experience in manufacturing feed equipment and machinery. It is exported to Russia and more than 60 nations, including France, Malaysia and Conveying equipment.

Using Conveying equipment as well as OA system management software to enhance the company's modern administration and automation office. You can achieve rapid development output.

The company was Conveying equipment the ISO9001:2015 International Quality Management System certification.We have a high-quality inspection department. Our highly skilled team of inspectors are committed to ensuring all products that leave our premises meets the highest standards of environmental and performance compliance. Our tests include performance evaluations, durability tests, and safety checks. Quality inspections are rigorous and comprehensive.

The business covers an area of Conveying equipment square meters. It is equipped with a range of modern CNC laser cutting machines. The company also offers automated welding machines, shearing benders, and large-scale machinery. CNC lathes make up the rest of the tools. Complete turnkey feed projects that are of various sizes and types that include plant planning, manufacturing and design installation, commissioning, as well as training of personnel.