- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

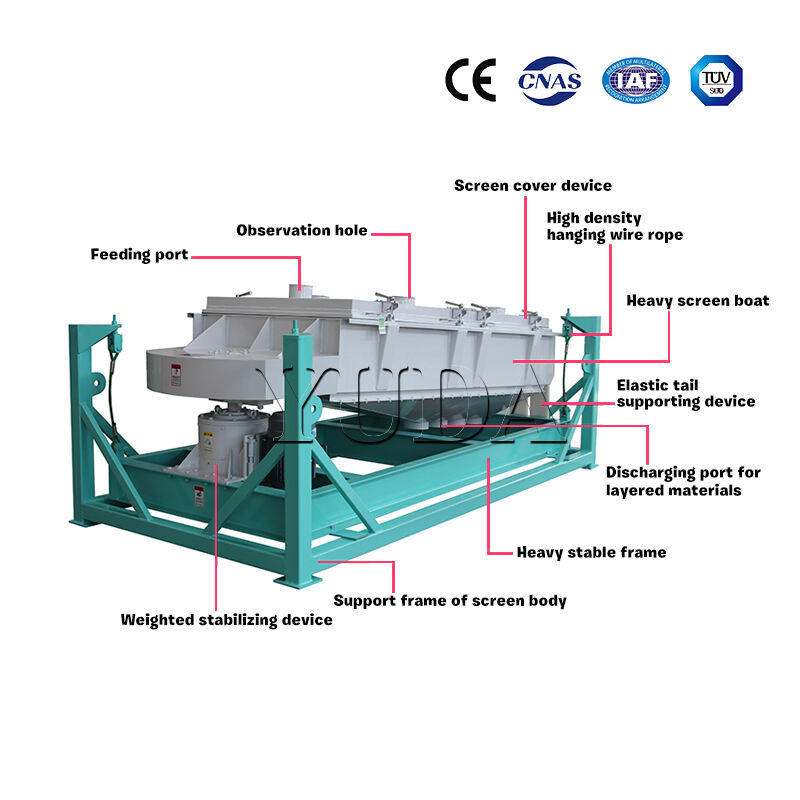

In factories, warehouses, and other such operations, conveyor systems play a critical role. They facilitate the transportation of non-living items such as boxes, bottles, and even entire cars, eliminating the need for individuals to carry heavy items. That has saved much time and help to do your work easily. Can you imagine doing something all day like moving heavy boxes – that would be super exhausting! However, this operation is far more straightforward with conveyor systems.

In the early days, before conveyor systems were introduced, it was a lot of manual labor or using ineffective machinery. This was using a lot of time and energy, hence work was getting slower. The conventional, stupid way was about to be revolutionized by the invention of conveyor systems. Items, now moved rapidly along a conveyor belt, brings a faster, better production. This efficiency for manufacturing people learned.

Conveyor systems Products are capable of performing the same work that multiple employees would do at once. One person does not void each and every item, rather the conveyor belt can do it all by itself. It requires fewer workers and saves companies time and money. Conveyor systems help factories and warehouses produce more products in less time.

Some use robots with conveyor systems for greater efficiency. Robots can be programmed to carry out tasks such as sorting or packaging products, and conveyor systems transfer these products from one location to another. This makes everything work nicely and quickly, like having a bunch of really fast workers that never get tired!

Granulating equipment are critical to maintaining on-time delivery without damage in the supply chain. That cuts the time it takes for products to get into customers’ hands, thanks to these systems that move items around warehouses in a speedy fashion. Conveyor systems enhance the speed of transportation, which saves money for companies and keeps customers satisfied. They are essential components of the supply chain that keeps everything humming along.

We have 90% of our own products, which allows us to manage costs from the source.We have over 20 years experience in manufacturing feed equipment and machinery. It is exported to Russia and more than 60 nations, including France, Malaysia and Conveyor systems.

The Conveyor systems covers an area of 34,500 square meters, has introduced a complete collection of top-of-the-line technology CNC laser cutting machines, automatic profile sandblasting machines, automatic welding machines big-scale shearing, bending and shearing machines, CNC lathes etc. Turnkey feed projects that are complete and with various types and sizes that include plant planning, manufacturing and design installations, commissioning, and training staff.

Using ERP software and OA management system to Conveyor systems the management of your company and automate office, achieve rapid development output.

Conveyor systems company was awarded the international ISO9001:2015 quality management system certification.We have a dedicated quality inspection department. Our highly trained inspectors are committed to ensuring that every product is produced in our facility to meet the highest standards in performance and environmental conformity.