- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

Grinding hammers are useful tools that can assist you with a variety of projects at home. These tools can be used for shaping, smoothing, or removing material United Nations such as wood, metal or stone. If you are not familiar with the use of a grinding hammer, it may be a bit frightening at first. But a little help and practice and you will know how to use this tool in no time

First, you need to understand some basic parts and how it works before you start using a grinding hammer. 5 things a grinding hammer: handle, motor, spinning disk, grinding wheel You hold the hammer and the motor spins the disk that grinds the wheel to work.

Plug the power cord into the power outlet before using a grinding hammer. Then ride the hammer on and off by gripping the handle and pressing the power switch. The speed control knob can be used to change the speed of the spinning disk. After the hammer is on, you have to apply the grinding wheel to your working surface.

Something else to consider is how powerful is the hammer. The hard-hitting hammer you need to get through tougher materials such as metal or stone. And consider the size and weight of the hammer — you want an easy-to-hold tool that you can use extensively.

Always keep your environment clean and free of clutter to prevent tripping. For a grinding hammer Products, hold the handle firmly and do not work with wet hands or in wet places. Lastly, don't use the hammer close to flammable materials and do not use hammer in a confined space without proper ventilation.

These are a few tips to work better with your grinding hammer. Be sure to choose the correct grinding wheel suitable for the material you are working with. Wheels vary, so be sure to get the appropriate one for the material you’re planning to grind.

And take breaks as necessary so your hands and arms don’t tire. In order for your grinding hammer mill to function properly, it is crucial that you keep it clean and well-maintained. Inspect the shoes for wear and tear, replacing worn parts as necessary.

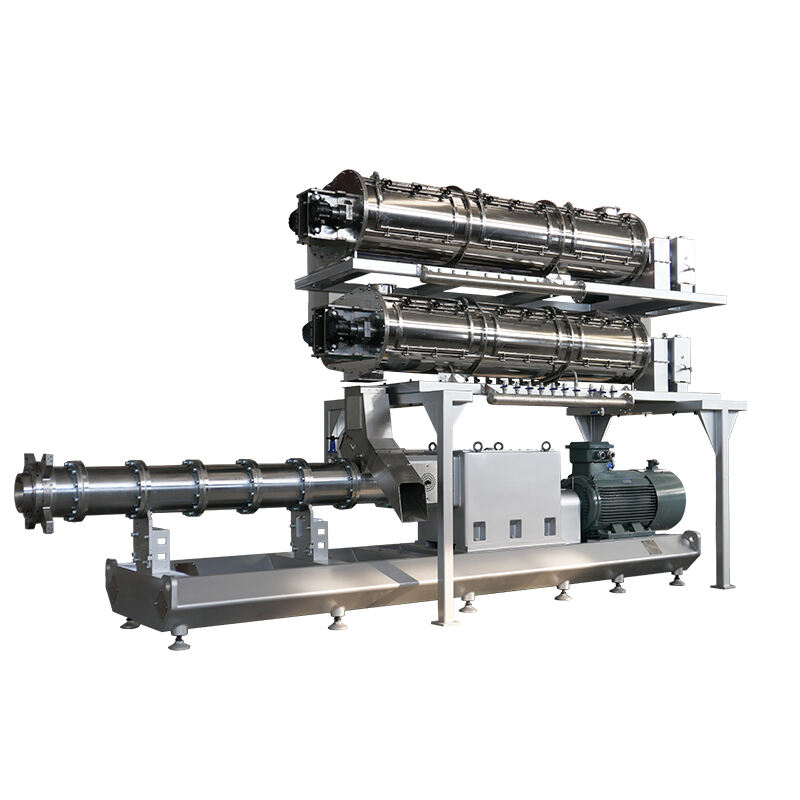

The company covers an area of 34.500 square meters and has installed a complete set of high-tech CNC laser cutting machines. It also offers automatic welding machines, Grinding hammer, and large-scale machinery. CNC lathes are part of the tools. Complete turnkey feed projects of various sizes and types that include plant planning, production and design installations, commissioning, and training of personnel.

Grinding hammer of ERP software and OA management software to boost the efficiency of management in the business and streamline office operations, you can achieve speedy development output.

We manufacture Grinding hammer percent of our products ourselves. This allows us to reduce costs at the location.We have more than 20 years of experience in the manufacturing of feed machinery, equipment and supplies exported to Russia, France, Malaysia, South Korea, Canada, Egypt, Australia and other more than 60 countries. We can also assist the user to establish the best technical advice, product sales, technical training, and maintenance network.

The company was Grinding hammer the ISO9001:2015 International Quality Management System certification.We have a high-quality inspection department. Our highly skilled team of inspectors will ensure the quality of every product that leaves our premises meets the highest standards of performance and environmental compliance. Our tests include evaluations of performance testing, durability tests, as well as safety checks. Quality inspection process is rigorous and thorough.