- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

For grinding materials "smaller," such as further reducing big grains (corn, wheat, etc.) into fine powder, hammer mill does the job. This article will help you understand how this process works and why it matters.

This is with hammer mills are great to get larger materials down into smaller chunks. It’s like taking a hammer to a giant boulder and breaking it up into little pebbles. It also makes the materials easier to work with and mix together. It also produces uniformly-sized pieces, which is very useful in many fields.

A hammer mill grinds whatever you put in to the same size. It implies that when you combine various elements together, then they will blend totally and effectively. Think of baking cookies and ensuring all your flour is the same size — it’s the same concept!

Grains are not the only substance ground on a hammer mill. This can do a lot; you can grind spices, herbs and even plastic! This means that it is a useful tool in very diverse fields such as food preparation and recycling.

A great thing about hammer mill grinding is that it is adaptable to various application. Depending on whatever material you are utilizing, you can change the speed and scale of the hammers to get the proper grind. This indeterminacy renders it useful in diverse fields like agriculture, medicine and mining.

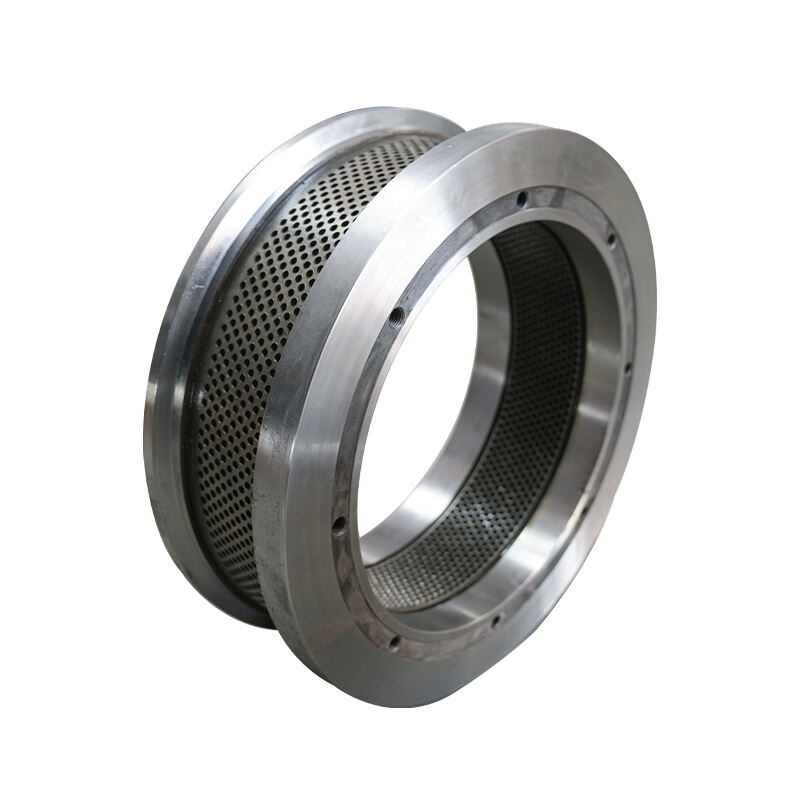

Innovative technology in hammer mill grinding Products allows you to work smarter and more efficiently. With this new tools, the computer systems and the fast hammers, the grinding of any material would definitely be faster and better. That means you can accomplish more in a shorter amount of time, which can save money as well as energy.

We manufacture Hammer mill grinding percent of our products ourselves. This allows us to reduce costs at the location.We have more than 20 years of experience in the manufacturing of feed machinery, equipment and supplies exported to Russia, France, Malaysia, South Korea, Canada, Egypt, Australia and other more than 60 countries. We can also assist the user to establish the best technical advice, product sales, technical training, and maintenance network.

The company has been awarded the world-wide ISO9001:2015 quality management system certification.We have a high-quality inspection department. Our highly-trained team of inspectors is dedicated to making sure the quality of every product that leaves our facility is in compliance with the highest standards of environmental and performance compliance. Our tests include performance evaluations along with durability tests, as well Hammer mill grinding. Quality Inspection procedures are thorough and thorough.

The business covers an area of Hammer mill grinding square meters. It is equipped with a range of modern CNC laser cutting machines. The company also offers automated welding machines, shearing benders, and large-scale machinery. CNC lathes make up the rest of the tools. Complete turnkey feed projects that are of various sizes and types that include plant planning, manufacturing and design installation, commissioning, as well as training of personnel.

Hammer mill grinding of ERP software and OA management software to boost the efficiency of management in the business and streamline office operations, you can achieve speedy development output.