- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

Ever wonder how the small pellets that are used for fuel and animal food are produced? This is all made possible by the die used in the pellet mill. Now, let's dive into the significance of the pellet mill die in pellet production, types of dies, selection criteria and maintenance tips.

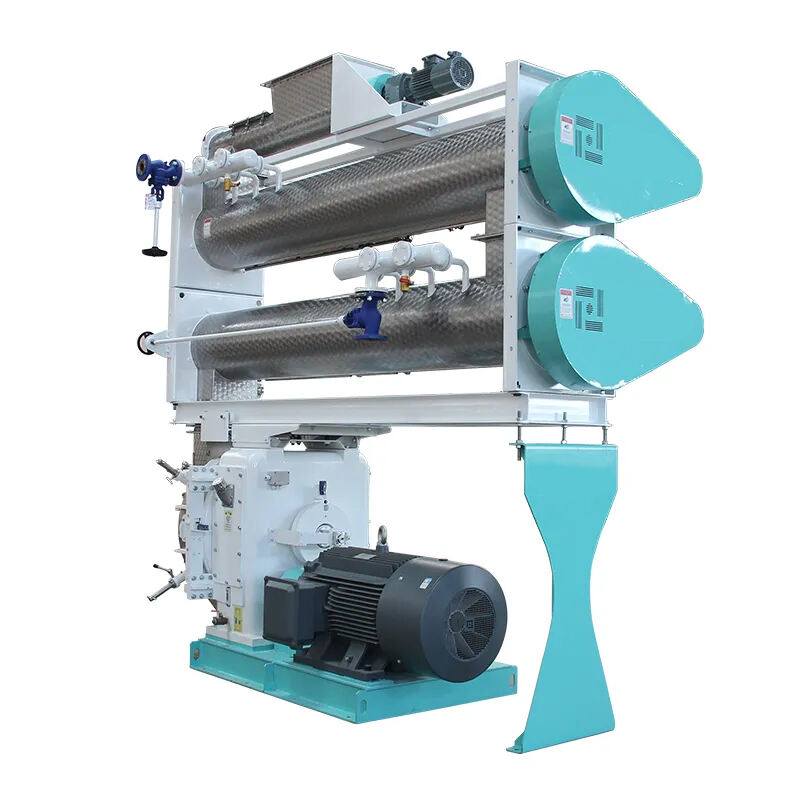

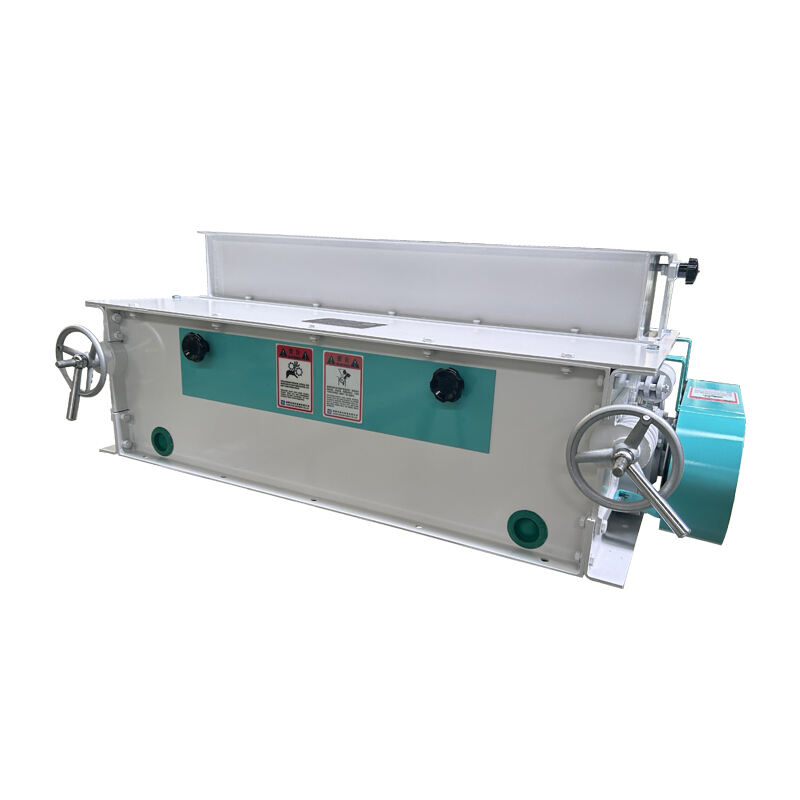

The two types of pellet mill die are the flat die and ring die. Pellets mill dies Are mostly used for small tasks or for at home. They are also easier to use and maintain than other types, but are limited in the amount of pellets they can produce. In contrast, ring die pellet mill die is most effective for heavy-duty applications and commercial use. This makes them faster and they can produce more pellets in less time.

When selecting a pellet mill die Products that meets your needs, consider which types of plant materials you’re working with, what size you want the pellets to be, and that the quantity you want to produce are factors to consider. When producing pellets, you require a die and a die made of durable materials that can withstand the pressure as well as heat. Professional or supplier consultation could be beneficial in determining the proper die.

Your pellet mill die will work nicely and produce nice pellets as long as you maintain it. Scrape frequently, look for damage, and last but not least, lubricate the moving components. Die-based problems like unequal pellet size tell you to adjust the pressure or temperature settings on the die to improve performance or to ensure perfect amounts of pellets.

The importance of the die of the pellet mill in the production of quality pellets used in biofuel, fodder, and the agricultural industry. By Granulating equipment controlling the quantity of pressure and heat in the die, manufacturers can create pellets equal in size, density, and moisture. Feeding animals, for burning well in biomass boilers or stoves, these quality pellets are necessary.

The company covers an area of 34.500 square meters and has installed a complete set of high-tech CNC laser cutting machines. It also offers automatic welding machines, Pellet mill die, and large-scale machinery. CNC lathes are part of the tools. Complete turnkey feed projects of various sizes and types that include plant planning, production and design installations, commissioning, and training of personnel.

The company was Pellet mill die the ISO9001:2015 International Quality Management System certification.We have a high-quality inspection department. Our highly skilled team of inspectors are committed to ensuring all products that leave our premises meets the highest standards of environmental and performance compliance. Our tests include performance evaluations, durability tests, and safety checks. Quality inspections are rigorous and comprehensive.

Using ERP software and Pellet mill die to boost the efficiency of management in the business and automate office, achieve quick development output.

We make 90 percent of our products ourselves. This allows us to control the costs at source.We have more than 20 years of experience in producing feed machinery and equipment that's exported to Pellet mill die and more than 60 countries like France, Malaysia and South Korea.