- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

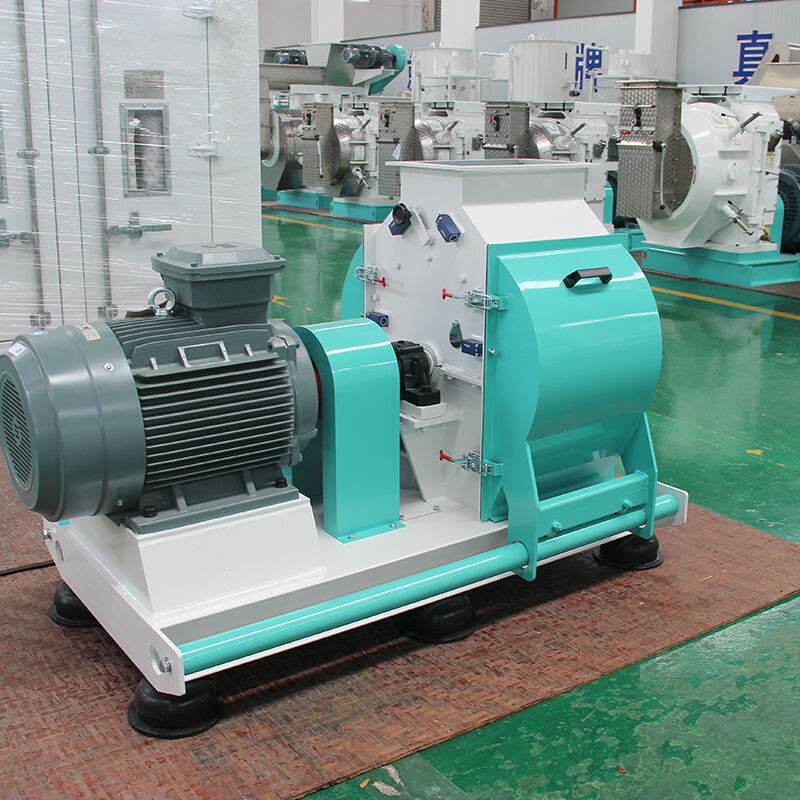

Turning leftover rice husks into something useful is a neat invention, a rice husk pellet making machine. At Shanghai Yuanyuda, we are proud to spread this great technology, which could enable our waste better processing.

Rice husks are those bits that are leftover when we make our rice. Farmers in the past discarded these husks by burning or trashing them, creating pollution. Thanks to the coffee husk pellet making machine will now we have transformed this waste material into convenient pellets that can be used as a fuel component, animal bedding and even fertilizer. This is good for our planet and reduces waste.

Rice husk pellet making machine functions deepen by squeezing rice husks out into small pellets for storage and transportation. This process makes it easier to use these husks after recycling them. For farmers and rice millers, their waste could be transformed into something valuable with this machine and it did not not even require much effort.

Rice husk pellet making machine Products is one of the most useful machines because it converts waste to useful products. These can then be used as fuel for stoves or heaters. It is possible to reduce fossil fuel consumption and benefit our planet by using rice husk pellets as fuels. It’s a win-win!

Goodbye hassle of rice meal disposal. Take a rice husk pellet making machine from Shanghai Yuanyuda Granulating equipment to quit worrying about a disposal. Rather than incinerating or discarding the husks, they can easily b into pellets with countless potential applications. If you're dealing with rice husks, this convenient solution can saves you money, time, and energy.

Rice husk pellet making machine of ERP software and OA management software to boost the efficiency of management in the business and streamline office operations, you can achieve speedy development output.

Rice husk pellet making machine manufacture 90 percent of our own products. This lets us reduce costs at the source.We have more than 20 years of experience in the manufacture of feed machinery and equipment, which is exported to Russia, France, Malaysia, South Korea, Canada, Egypt, Australia and additional more than 60 countries. We also help users to develop an ideal technical consulting, product sales, technical training and maintenance service network.

The company was Rice husk pellet making machine the ISO9001:2015 International Quality Management System certification.We have a high-quality inspection department. Our highly skilled team of inspectors will ensure the quality of every product that leaves our premises meets the highest standards of performance and environmental compliance. Our tests include evaluations of performance testing, durability tests, as well as safety checks. Quality inspection process is rigorous and thorough.

The company covers an surface of 34.500 Rice husk pellet making machine. The company has installed a complete set of modern CNC laser cutting machines. It also offers automatic welding machines, shearing, bending, and large-scale equipment. CNC lathes are among other tools. We can take on a variety of sizes and types of turnkey complete projects for feed, which include the entire plant design, planning, equipment manufacturing Installation and commissioning and personnel training.