- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

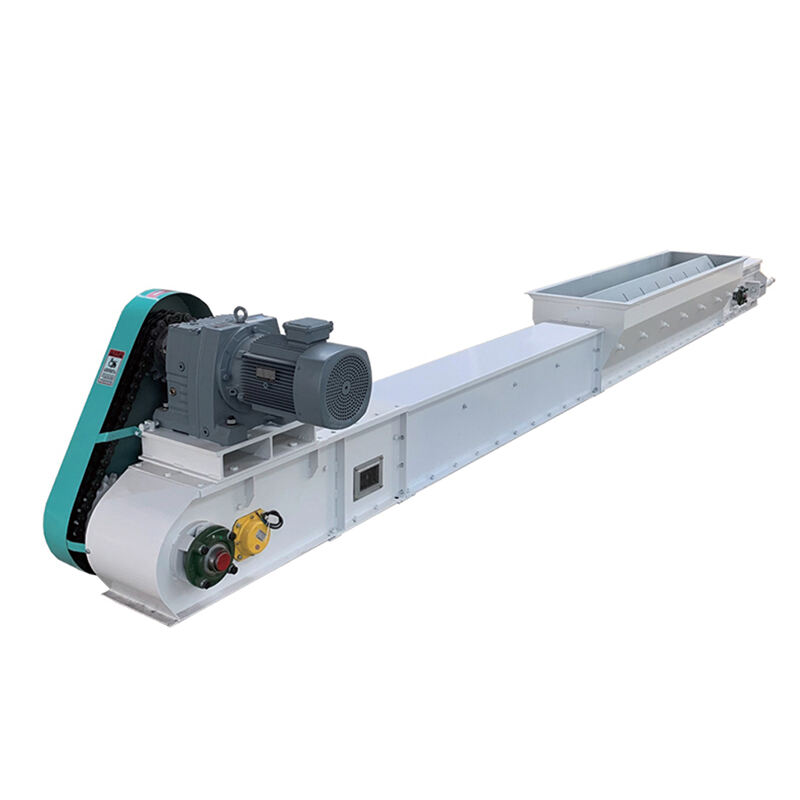

What is Wood Pellet Press Machine? Wood pellet press machines are pretty cool machines to use for producing wood pellets as fuel. They work on a kind of sorcery, transforming wood scraps into tiny pellets, which can burn for heat. Shanghai Yuanyuda wood pellet press machine supplier. If your business requires large quantities of wood pellets, you may want to consider purchasing a wood pellet press machine. These are just the machines that will do good for you and bring a significant change in your business.

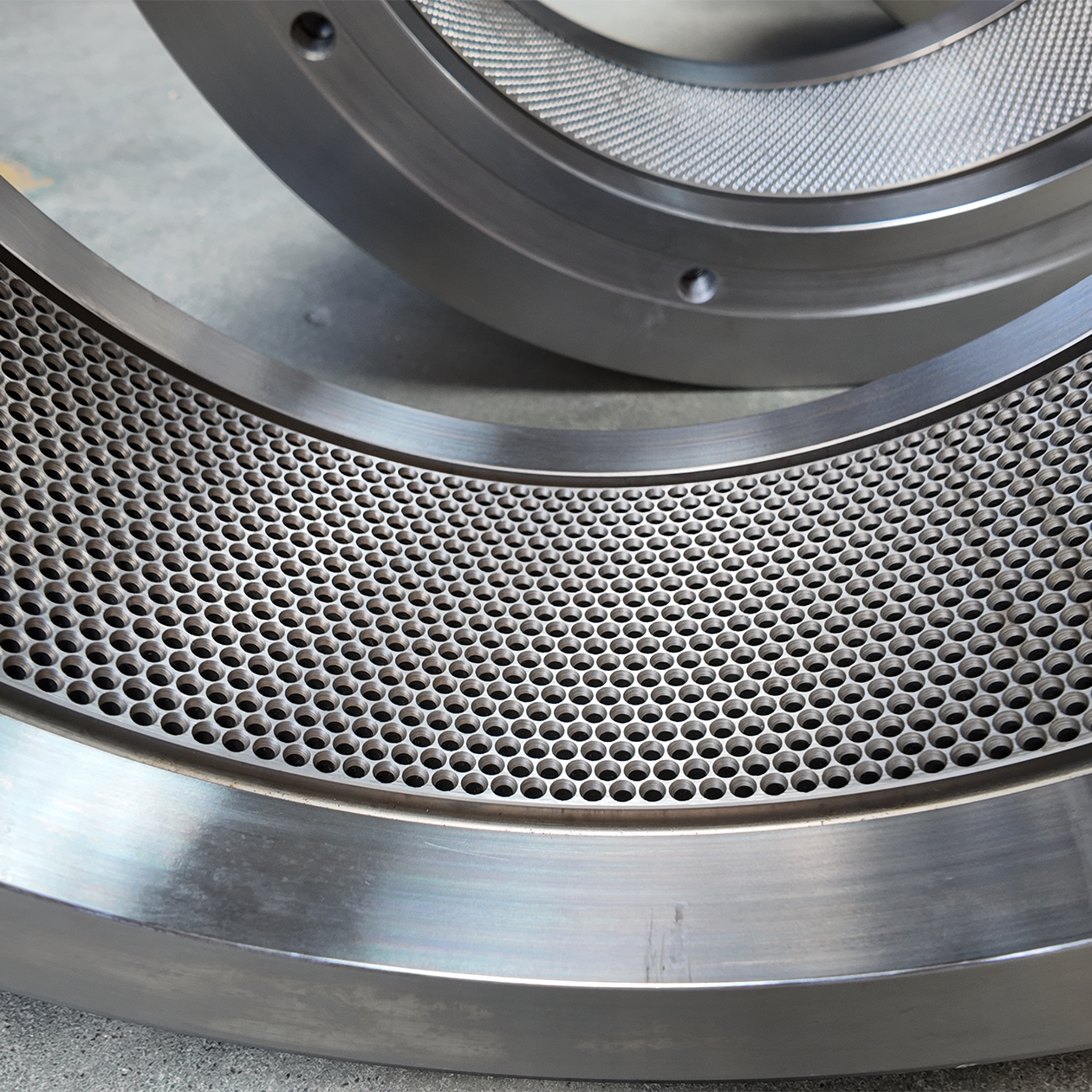

The wood press machine will take wood waste and press it into pellets. These pellets can be burned in appliances such as stoves and boilers. Pelletizing is the process of making wood pellets. First they are crushed into small pieces. They are then compressed under high pressure and formed into pellets. After that, the pellets are cooled and dried, preparing them for use.

If you own a wood pellet press machine(s) from Shanghai Yuanyuda then you are lucky! The machine lets you make your own wood pellets, rather than purchasing them from someone else. Doing so can help you save money and make your business more efficient. You can customize the pellets precisely how you want them. Also, using a wood pellet press machine contributes towards environmental sustainability as it utilizes wood waste that may be discarded.

In this context, Products purchasing a wood pellet press machine can significantly benefit your business. One of the main reasons for this is that you can save money on wood pellets by making them yourself instead of buying them. Ensure the pellets are good quality and meet your needs as well. Therefore, a combined wood pellet press machine can reduce your dependence on other suppliers, enhance your control over your business, and help you gain success.

There are some considerations to make when selecting a wood pellet press machine from Shanghai Yuanyuda. First ask yourself, how much wood will you process and how big a pellet do you need? Different machines are capable of different amounts, so be sure to select one that works for your needs. So also consider the power source of the machine and that it is compatible with what you have. Lastly, look for reviews and recommendations to find a good, reliable machine.

Once in possession of a Granulating equipment, maintaining it to ensure a long lifespan is key. This is why regular maintenance is so crucial to keep the machine running in tip-top shape. That means cleaning it regularly, looking for loose or worn parts, and lubricating moving parts. Don’t worry if you have any issues with the machine! Most of the problems are easily resolved by consulting the manual or contacting the manufacturer. Maintaining your wood pellet press machine ensures that it serves your business for a long time.

Wood pellet press machine manufacture 90 percent of our own products. This lets us reduce costs at the source.We have more than 20 years of experience in the manufacture of feed machinery and equipment, which is exported to Russia, France, Malaysia, South Korea, Canada, Egypt, Australia and additional more than 60 countries. We also help users to develop an ideal technical consulting, product sales, technical training and maintenance service network.

The company Wood pellet press machine an surface of 34.500 square meters. It is equipped with a range of high-tech CNC laser cutting machines. It also offers automatic welding equipment, shearing, bent equipment, as well as large-scale. CNC lathes are part of the tools. Take on various sizes and types of turnkey complete projects for feed, including the entire plant design, planning manufacturing of equipment installation and commissioning as well as training for employees.

The company has been awarded the Wood pellet press machine ISO9001:2015 Quality Management System certification.We have a quality-control inspection department. Our team of highly trained inspectors is committed to ensuring that each product that leaves our facility meets the highest standards of environmental and performance compliance. Our tests include performance evaluations as well as durability tests and safety checks. Quality Inspection procedures are thorough and comprehensive.

Wood pellet press machine ERP software and OA management system to enhance the management of your company and to automatize office work, achieving rapid development output.