Producing high-quality pellet feed efficiently is the most important factor in profitability and meeting market demand. Whether you are producing poultry feed, livestock feed, or aquaculture feed, even minor adjustments to the production line can result in significant changes to the final product. Here are some practical ideas that are easy to implement and can improve efficiency without requiring any technically complex adjustments.

Keep Your Equipment Well-Maintained

Uninterrupted production depends on regular maintenance.

Ensure that particle mills and hammer mills are cleaned regularly to prevent blockages.

To ensure particle uniformity, check and replace worn dies, rollers, and hammers.

Lubricate moving parts to minimize friction and energy waste.

Well-maintained machines work faster, longer, and with fewer breakdowns.

Optimize Raw Material Preparation

Proper grinding and mixing of ingredients can improve pellet quality.

A hammer mill should be used on an appropriate screen to ensure uniform pellet size (finer pellets for poultry and coarser pellets for livestock).

Mix the ingredients to avoid separation of nutrients.

Adjust the moisture content (or 12-16%) to form pellets.

Consistent raw materials = larger pellets and denser production.

Adjust the granulator settings to obtain maximum output.

Ring die thickness—Hard pellets are made with thicker molds, at the cost of slower speed. Diagnose the ideal balance based on your needs.

Drum pressure—There must be adequate pressure to keep the pellets in shape without deforming the machine.

Steam regulation—Light steam softens the ingredients, making them easier to compress into pellets.

With minor modifications, production speeds can be increased by a few or even tens of percentage points without compromising quality.

Reduce downtime with intelligent workflows

Optimize your production line layout to minimize downtime between grinding, mixing, and granulation.

Keep spare parts (ring die , rollers, screens) on hand so you don't have to wait long to replace them.

Train employees to identify minor issues promptly and correct them before they cause production changes.

Smooth operation = more granules per hour.

Monitor energy usage to achieve cost savings

Overworking machines wastes electricity. Operate equipment at maximum capacity.

When you want to upgrade your granulator, consider using energy-efficient motors.

Production should be scheduled during off-peak energy supply hours.

A decrease in energy prices equals an increase in profits.

Test and Improve Pellet Quality

Test the hardness of the pellets (they should not break easily).

Make them the same size and shape so that animals can eat them more easily.

Change the formula when the pellets are too soft or too hard.

Improve the pellets to satisfy customers and reduce feed waste.

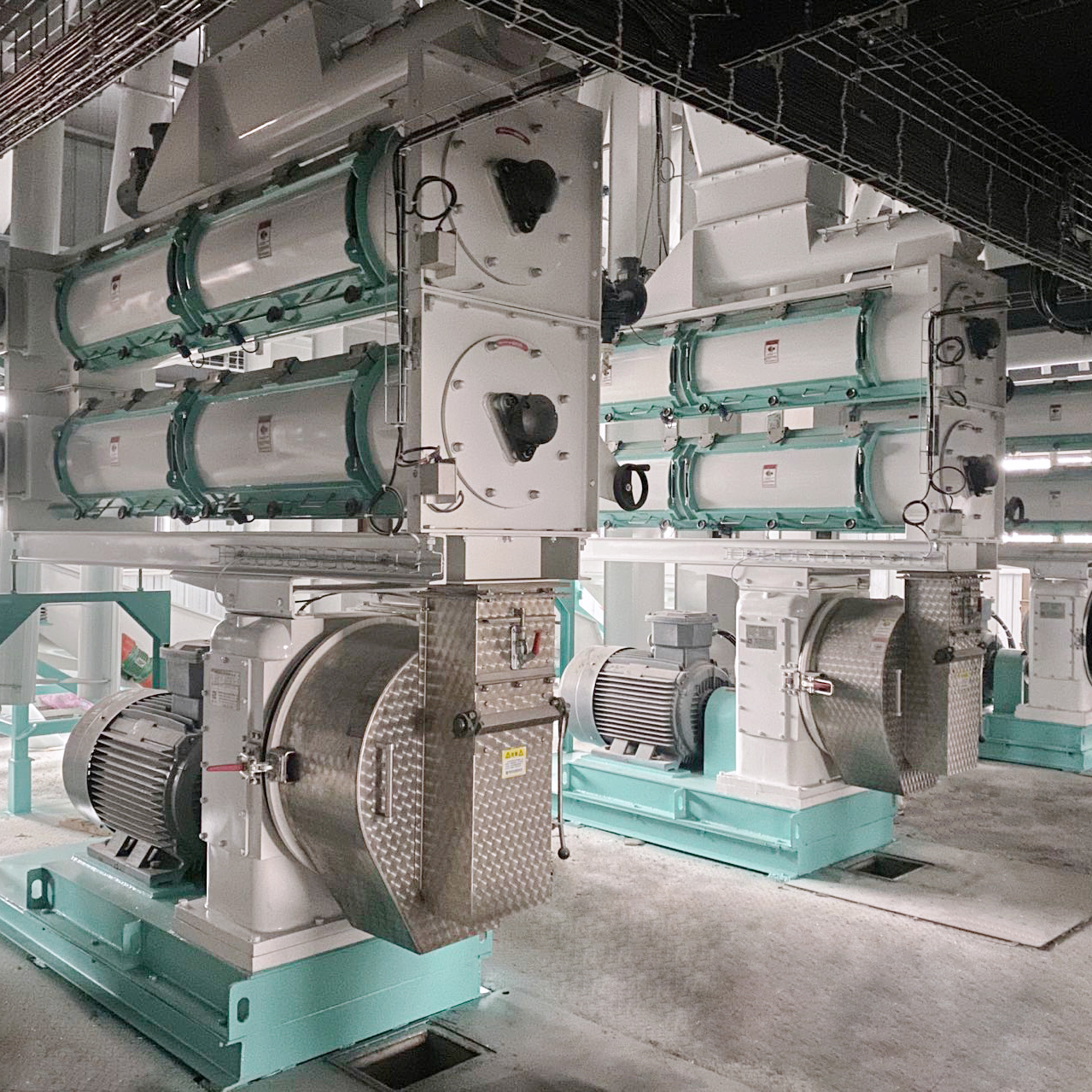

Final Tip: Invest in Reliable Equipment

The difference lies in high-quality granule machines and supporting machinery. When your current machine is worn out or running slowly, you can recoup your expenses in a short period of time by increasing production and reducing maintenance costs.

Shanghai Yuanyuda international trade co. Whether it's a hammer mill or a pellet mill, our equipment will give you the best productivity in this area. Contact us today to increase your feed production!

EN

EN