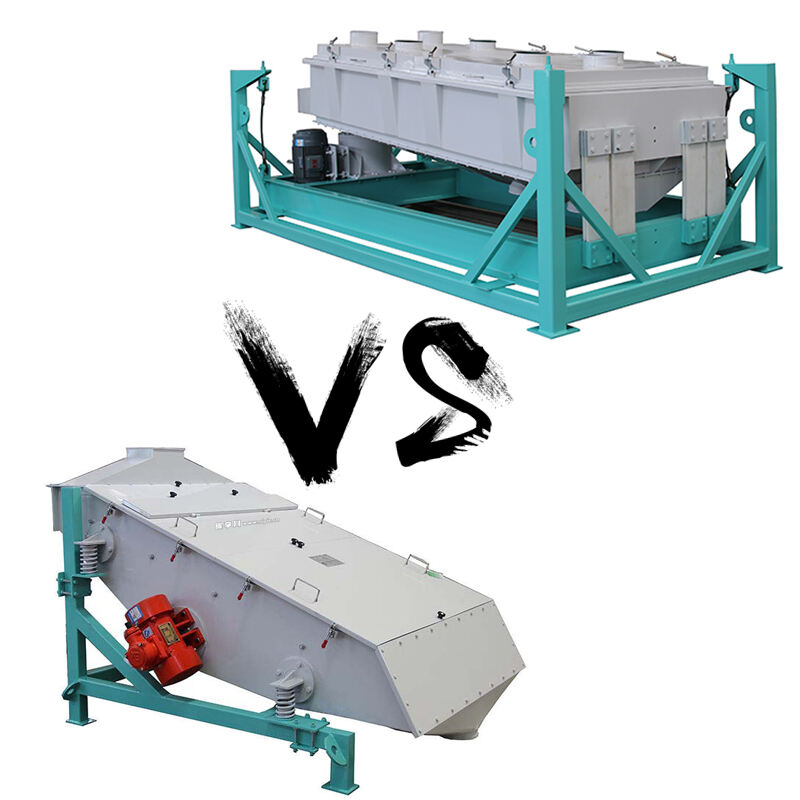

Yuanyuda provides vibrating and rotary pellet screeners that are aimed at addressing a particular set of screening requirements in the production of feeds. The decision of which to use is left to the nature of materials, production objective and operating needs but each system offers different benefits that can maximize quality control of the pellets.

Material Compatibility

Vibrating screeners work best with coarser, clumpy, or irregularly shaped materials.

Their trembling motion successfully disrupts small agglomerations and is therefore suitable for the initial screening of feed pellets of different sizes.Rotary screeners, on the other hand, work best with standard-sized, fine to medium-sized pellets. This makes their rotational movement gentle enough, which is appropriate for delicate pellets that require careful grading without breaking.

Efficiency in Production Flow

Vibrating screeners are typically used in high-volume production lines.They vibrate constantly, achieving a high throughput and thus efficiently processing large quantities of feed pellets in a short time.Rotary screeners process smaller quantities in a single run but are more accurate at separating pellets by individual size, which is crucial for final quality checks as consistency is essential.

Maintenance and Durability

Yuanyuda vibrating screeners, with their simplified design, fewer moving parts, and consequent reduction in maintenance and downtime, once again excel in reducing operational costs.It is advantageous to consider their low-maintenance equipment services. Rotary screeners, which have more complex components, require regular checks to ensure trouble-free operation. However, Yuanyuda's engineering expertise makes them highly durable and capable of operating efficiently regardless of usage intensity.

Application Scenarios

Pre-processing: Removal of oversized particles after pelletizing. Vibrating screeners perform well in preprocessing phases.They fit seamlessly into high-speed production lines where speed and quantity are the primary goals. Rotary screeners, however, excel in post-production quality control and can be used to ensure that finished feed pellets meet the strictest size requirements—necessary for specialized feeds such as aquatic or pet food.

In summary, neither vibrating nor rotary screeners can be considered superior to the other; each is applicable only to specific requirements.Yuanyuda has developed screeners that take these differences into account, offering flexible screening solutions: vibrating screeners for high-volume batch screening, and rotary screeners for accurate, gentle grading.This flexibility ensures that customers can choose the best equipment to optimize their feed production flow and pellet quality.

EN

EN