Yuanyuda Bucket Conveyor is applicable to conveying all kinds of granules, powder, small blocks and low-abrasive materials. Drawing on its 80 years of practical engineering experience and field-proven performance, Yuanyuda developed the conveyor with a focus on increasing material flow in each operation to reduce equipment wear and meet specific jobsite requirements.

The Core Mechanism of the Vertical Transport Working Process

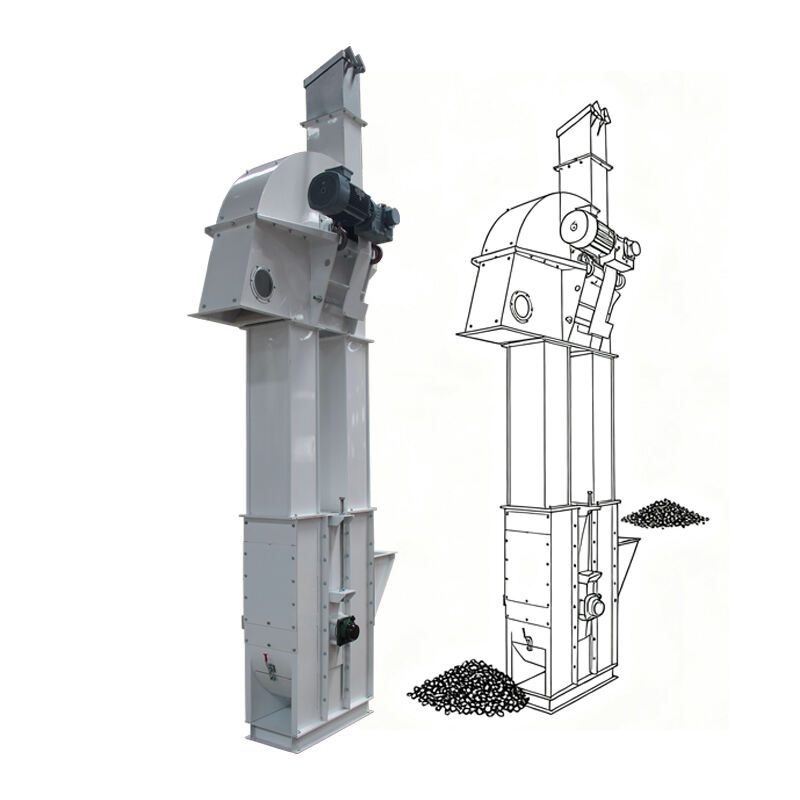

The design of the bucket conveyor of Yuanyuda is simple yet helpful. The conveyor collects materials using special buckets attached to a heavy-duty lifting rig. It transports the material upwards by lifting the material with these buckets, ensuring that granular or powdery materials are conveyed upward effectively. This type of design is highly effective in controlling the loss of material being transported, as demonstrates its commitment to a safe and efficient method for shifting materials.

Design Features Enhancing Handling Efficiency

Other structurally provided features of the conveyor are performance improving features. The Casing adopts a four-angle sealed casing design with one-time molding, which ensures stable formation, good plasticity, high rigidity, less dust emission and material return. It also offers an optional self-cleaning base to reduce operational stalling, as well as a split head wheel design that lowers the cost of rubber replacement and extends the equipment's runtime.

Versatile Use Across Multiple Industries

In industries such as food, feed, chemicals, building materials, grain processing, and oil processing plants, the Yuanyuda Bucket Conveyor is the most suitable material handling equipment for scenarios including grain storage, port docks, beer processing, and multi-process operations. For powdery and granular substances, explosion-proof covers and pressure balance devices can also be used based on material characteristics and industrial requirements; additionally, there are other feeding methods available for different materials.

For Other Safe Working and Upkeep Requirements

It is safe to use due to its reliable safety configurations. Additionally, key components such as main wheels, high-strength lifting belts, chains, and high-strength buckets are manufactured in-house, which helps ensure timely maintenance checks. By using the appropriate bracket, the conveyor achieves smooth material conveying, high efficiency, low failure rate, long service life, and continuous point feeding of materials—all of which meet the equipment's operational requirements.

In short, the Yuanyuda Bucket Conveyor is an excellent partner for logistics transportation and vertical transportation. It offers smart functions, supports large-scale applications, and provides robust safety and maintenance support. Currently, Yuanyuda has established itself as a reputable brand specializing in material handling and a reliable solution provider, delivering simplified material flow and increased productivity to its clients.

EN

EN