- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

Good morning, everyone! Let's discuss about feed milling equipment today. Have you ever wondered how the delicious pellets chickens and cows eat are produced? The solution is in feed milling equipment! We will explore the key components of modern feed milling equipment include: how to select suitable machinery for your farm, why it is important to service your feed milling machinery, benefits of quality feed milling equipment and u0022whatu0027s newu0022 in feed milling equipment and the new changes that speed up and improves feed milling.

So how do you go about selecting the appropriate feed milling equipment for your farm? It’s like choosing the right tool for a job. It says you need to consider really how large your farm is, but how many different types of animals you have, and like how much feed you need to produce. For example, it may not make sense to invest in a large Farm Milling machine if you only keep a small number of animals on a small piece of land. But if you have a large farm with many hungry livestock, you might need a large and improved device to cater to the demand of feed.

Why is it important to care for feed milling equipment has a lot to do with the care of your toys to prevent them from breaking. Regular attention helps the organic fertilizer pellet mill machines operate smoothly and avoids costly repairs. You need to clean the machines regularly, inspect them for any damage, and change any worn-out parts. With proper maintenance of your feed milling equipment, you can affix a long life guarantee and great feeds for your animals.

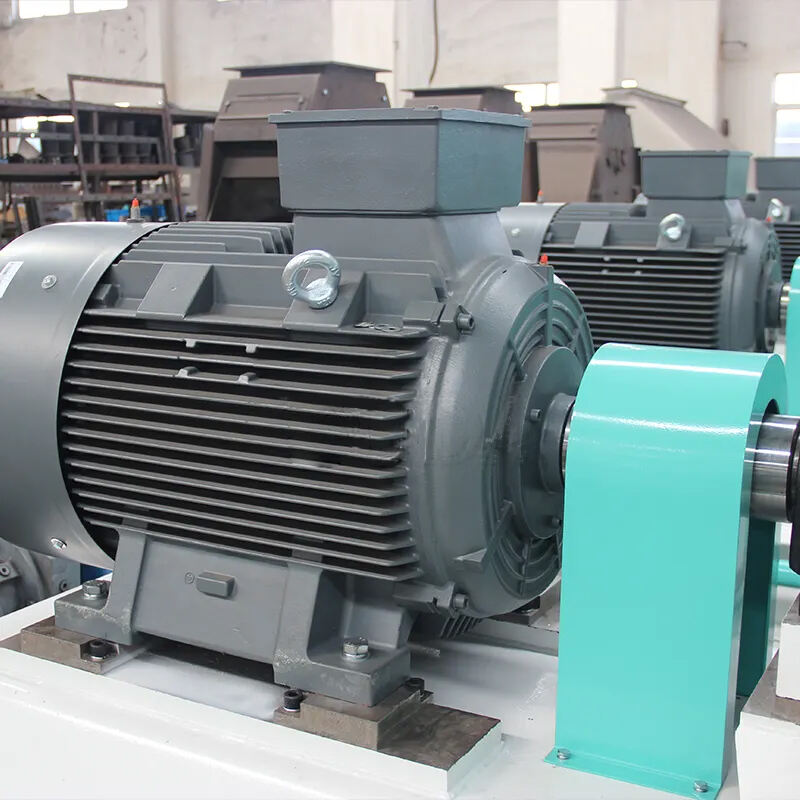

Same like getting a pair of good shoes getting high quality feed milling machine has its own benefits. They might be more expensive at first, but in the long run, they will last longer and operate better. Well made equipment is much more efficient, produces superior feed, and requires less maintenance. It saves time and money while providing your animals with a nutritious and delicious feed.

Here are some ideas to keep you and your feed milling in the game way up until 2015. The feed industry is not static; technology is always evolving and improving, including feed milling equipment. Really neat things include automation of the mill process, sensors that identify and remove bad things in the feed, feed grinder mixer and designs that save energy and reduce waste. These new concepts and ideas improve the speed and quality of feed milling and contribute to protecting the environment.

Using ERP software and Feed milling equipment to boost the efficiency of management in the business and automate office, achieve quick development output.

We have 90% of our own products, which allows us to manage costs from the source.We have over 20 years experience in manufacturing feed equipment and machinery. It is exported to Russia and more than 60 nations, including France, Malaysia and Feed milling equipment.

The company was Feed milling equipment the ISO9001:2015 International Quality Management System certification.We have a high-quality inspection department. Our highly skilled team of inspectors are committed to ensuring all products that leave our premises meets the highest standards of environmental and performance compliance. Our tests include performance evaluations, durability tests, and safety checks. Quality inspections are rigorous and comprehensive.

The company Feed milling equipment an surface of 34.500 square meters. It is equipped with a range of high-tech CNC laser cutting machines. It also offers automatic welding equipment, shearing, bent equipment, as well as large-scale. CNC lathes are part of the tools. Take on various sizes and types of turnkey complete projects for feed, including the entire plant design, planning manufacturing of equipment installation and commissioning as well as training for employees.