- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

General Introduction to Industrial Hammer Mills These are frequently used to process a variety of materials such as grains, wood and minerals in factories and workshops. Read on to learn more about how these machines operate, and why in particular they are so useful in the manufacturing process.

Industrial hammer mills are versatile machines that can crush, grind, or pulverize many different materials. They have big hammers which beat the material and reduce it in size. That's called size reduction, and it's essential for a lot of manufacturing jobs.

They let factories operate more smoothly and efficiently. These machines enable workers to turn in their work quicker, and require less material to do so, as they are known to quickly reduce materials. That allows factories to produce more goods and save costs. Hammer mill has a great significance to the maintenance of these places, which include farms, food factories, and mines.

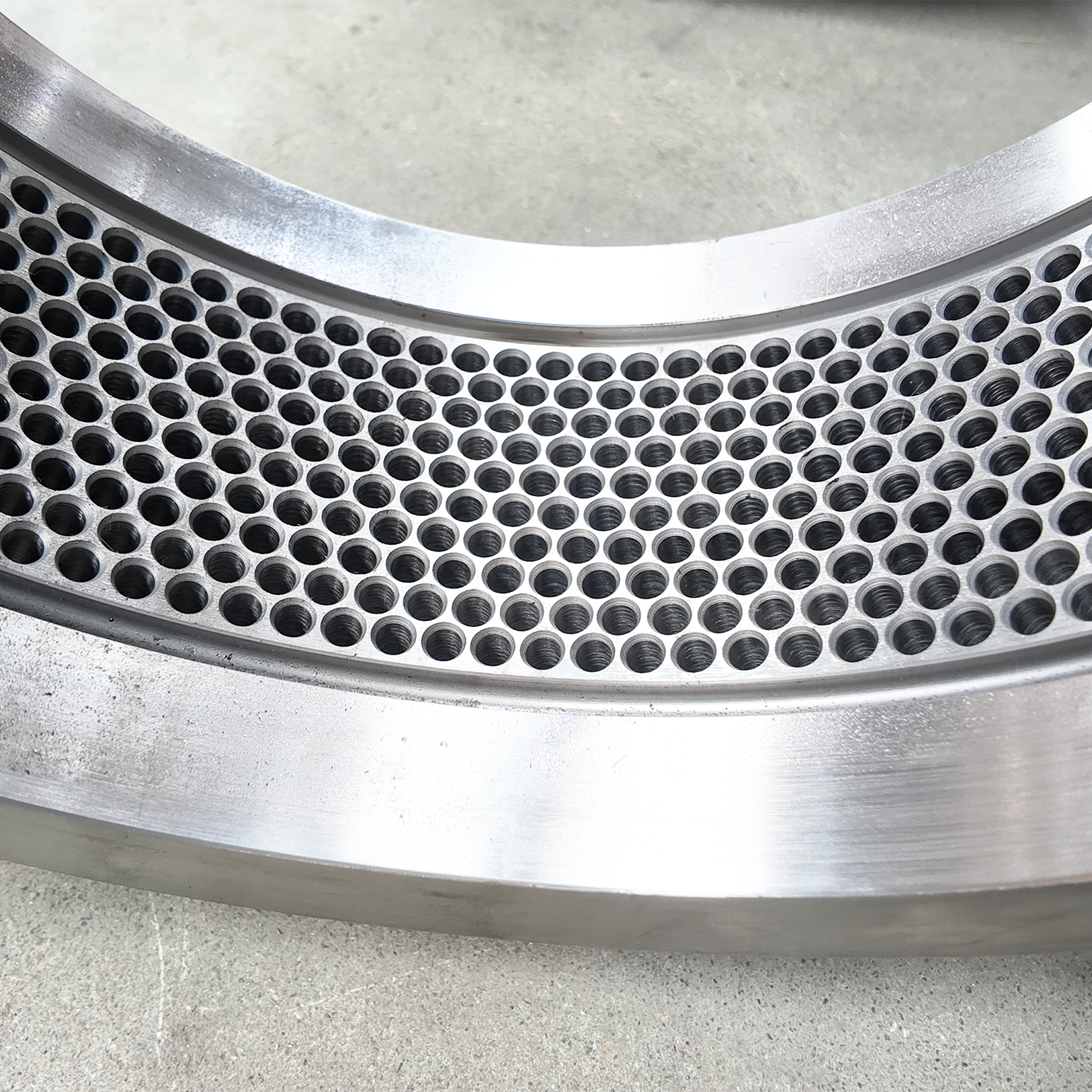

The industrial hammer mill consists of the following key components working together to break materials. These parts consist of a rotor, hammers, a screen, and a feed chute. The rotor spins with hammers that hit the incoming material. The screen determines the size of the finished product, and the feed chute allows materials to enter the machine for processing. Operating a hammer mill is easy. You feed in the material, it is hit with hammers and it is broken down into smaller bits.

So, here are some considerations when choosing a hammer mill. You have to know what kind of material you’re going to use, how small you want the pieces to be and how much material you want to process. Different hammer mills are designed for different jobs, so it pays to spend a few minutes choosing the right model for the job at hand. A reliable supplier can help you identify the most suitable hammer mill for you.

Environmental benefits of hammer mills Industrial hammer mills Products are also good for the environment. These machines allow businesses to deal with materials better and cut down on waste, which gives them a lesser impact on nature. Mixing leftover crops into animal feed using a hammer mill, for example, helps reduce waste en route to landfills in farming. In general, hammer mills help make businesses more environmentally-friendly.

The company covers an area of 34.500 square meters and has installed a complete set of high-tech CNC laser cutting machines. It also offers automatic welding machines, Industrial hammer mill, and large-scale machinery. CNC lathes are part of the tools. Complete turnkey feed projects of various sizes and types that include plant planning, production and design installations, commissioning, and training of personnel.

The company has been granted the Industrial hammer mill international quality management system certification.We have a high-quality inspection department. Our highly-trained inspectors are committed to ensuring that every product we produce is meeting the highest standards of performance and environmental compliance.

We manufacture Industrial hammer mill percent of our products ourselves. This allows us to reduce costs at the location.We have more than 20 years of experience in the manufacturing of feed machinery, equipment and supplies exported to Russia, France, Malaysia, South Korea, Canada, Egypt, Australia and other more than 60 countries. We can also assist the user to establish the best technical advice, product sales, technical training, and maintenance network.

Industrial hammer mill ERP and OA system management software to improve the organization's management capabilities and automate the office. It will also help in achieving rapid development output.