- Home

- Solution

- Products

- About Us

- Performance Case

- News

- Contact

Having the suitable machine to prepare food for animals is necessary. With the various machines available, it can be difficult to determine which type is best suited for your needs. First and foremost, one thing most people have to consider is the price of the machine. In this writing we will take a look at the different types of those machines along with their prices, factors that can change such prices and what is really out of money in the end.

The first thing you need to know is that feed making machines can cost or make money, depending on what kind of machine it is. Manual machines, which are simple by design, can be as inexpensive as $50 each, while an electric machine that has bells and whistles can cost over a thousand. This is good information to have if you are searching for one of these machines.

Dependent on production capacity: Machines which are capable of producing large amounts of feed at bale require an additional investment than those that can produce less. If you need larger livestock or must feed several animals, it may benefit you to purchase a machine with higher capacity.

Size and weight Large, bulky machines are more expensive to make as well as they cost extra to ship. Esentially, that could cost you and their prices may be reflective of those pricings. When it comes to the machine itself, think about the size before you buy it if you have little room.

Special features: Certain feed making machines offer special features these are additional such as digital controls, automatic shut-offs and self-cleanup. While these extra add-ons can help make the machines a little simpler to use, such machines will generally be more expensive than the basic models.

After reading this, you should have an idea of what can affect the price of a feed making machine and precisely, whether it is worth it to invest in a more expensive model. Answer: It really just depends on your specific needs and goals. For a small farmer who only needs to make feed for a few animals, an inexpensive manual machine or electric machine may work just fine.

However, if you are operating a large-scale farm and require quite some quantity of feed at a time, then industrial machines could be considered. They can take on a lot of work, and they are built to last. It can be expensive to buy a good machine that is made for extensive use and produces even better results, but if you think about it this can actually save you money in the long run as there would be little need to pay out for repairs or replacement equipment.

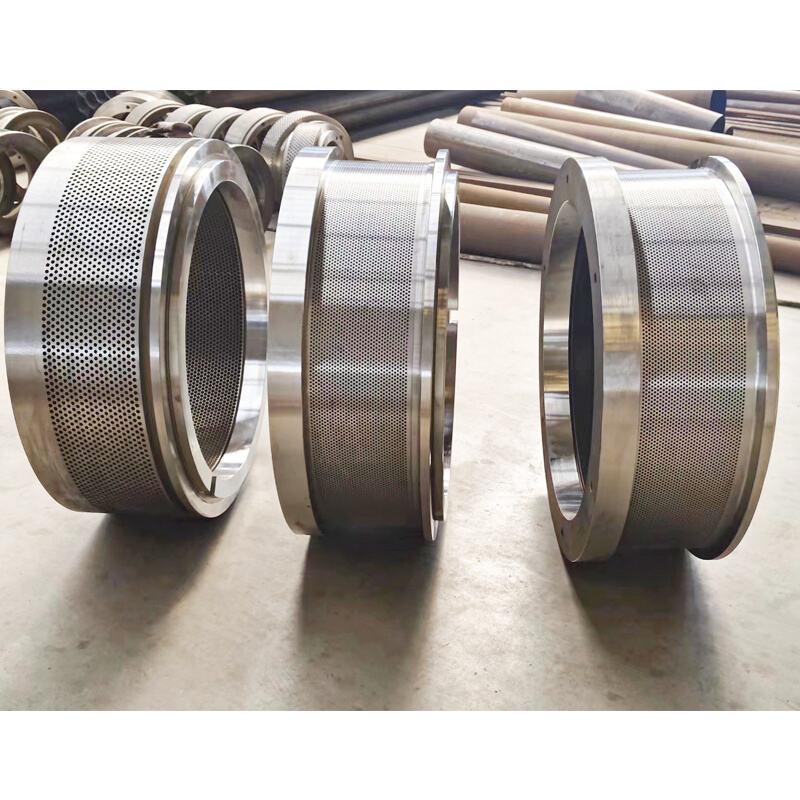

The company has a feed making machine price of 34.500 square meters. The company has installed a full set of modern CNC laser cutting machines. It also provides automated welding equipment, shearing, benders, and large-scale machinery. CNC lathes are part of the tools. Turnkey feed projects that are complete and of various types and sizes, including plant planning, manufacturing and design installations, commissioning, and training of personnel.

We manufacture feed making machine price percent of our products ourselves. This allows us to reduce costs at the location.We have more than 20 years of experience in the manufacturing of feed machinery, equipment and supplies exported to Russia, France, Malaysia, South Korea, Canada, Egypt, Australia and other more than 60 countries. We can also assist the user to establish the best technical advice, product sales, technical training, and maintenance network.

Using ERP software and feed making machine price to boost the efficiency of management in the business and automate office, achieve quick development output.

The company feed making machine price the prestigious international ISO9001:2015 Quality Management System certification.We have a quality inspection team that is dedicated to. Our team of highly trained inspectors will ensure all products that leave our facility is in compliance with the highest standards of performance and environmental compliance. Our tests include evaluations of performance testing, durability tests, as well as safety checks. Quality inspection procedures are rigorous and comprehensive.