With the rapid development of animal husbandry and breeding industry, the demand for refinement and high efficiency of feed production is growing. As one of the key equipments for modern feed processing, grease spraying equipment is becoming an important choice for feed enterprises to improve quality and efficiency by virtue of its advantages of precise spraying, energy saving and consumption reduction, and feed quality enhancement.

Precise spraying to improve the nutritional uniformity of feeds

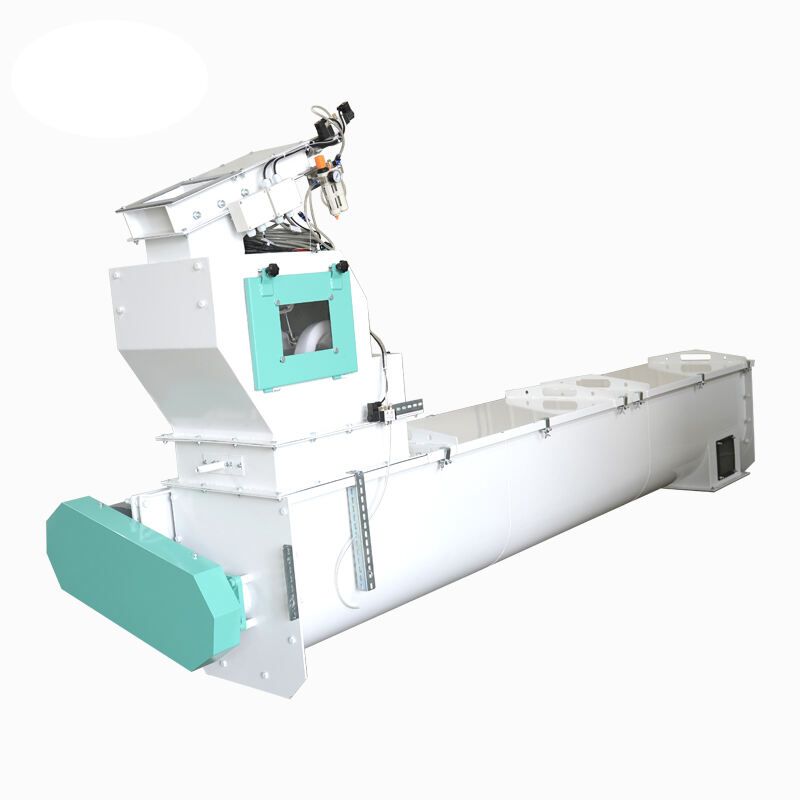

The traditional way of adding grease manually or by simple machinery can easily cause uneven mixing and affect the nutritional balance of feed. The grease spraying equipment adopts automatic control system, which can precisely adjust the spraying amount to ensure that the grease evenly covers each grain of feed, improve the nutritional consistency, enhance the palatability and digestive absorption rate of animals.

Improve production efficiency and adapt to large-scale production

Adding grease manually is inefficient and difficult to meet the high production demand of modern feed mills. Grease spraying equipment can be integrated into feed production line to realize fully automated spraying, which greatly improves the production efficiency and reduces manual intervention, especially suitable for large-scale production scenarios such as pellet feed and puffed feed.

Enhance feed stability and extend storage period

The grease spraying equipment can make the grease evenly wrapped in the surface of feed particles, reduce the generation of dust and improve the physical stability of feed. At the same time, the protective effect of the grease layer can reduce the risk of oxidation of the feed, extend the storage time and reduce the loss caused by mold or deterioration.

Flexibility to adapt to a wide range of feed types

Whether it is livestock and poultry feed, aquatic feed or special animal feed, the grease spraying equipment can adjust the spraying parameters according to different formula requirements to ensure the best spraying effect. Some high-end models also support data recording and intelligent adjustment, which is convenient for enterprises to optimize the production process.

Conforms to industry standards and guarantees production safety

The equipment is made of food-grade stainless steel, in line with feed safety production norms, easy to clean and maintain. The closed design reduces the risk of grease leakage and contamination and ensures a safe and hygienic production environment.

Conclusion

Under the background of high cost and intensified competition in the feed industry, post-spraying equipment is being upgraded from an “efficiency tool” to a “value creation hub”. Data show that feed enterprises that introduce intelligent post-spraying system, the average comprehensive energy consumption decreased by 18%, labor cost reduced by 40%, customer complaint rate reduced by 70%, truly realize the “cost reduction, quality improvement, efficiency, compliance” quadruple objective. After spraying technology will become the core competitiveness of feed machinery enterprises to seize the high-end market.

Table of Contents

- Precise spraying to improve the nutritional uniformity of feeds

- Improve production efficiency and adapt to large-scale production

- Enhance feed stability and extend storage period

- Flexibility to adapt to a wide range of feed types

- Conforms to industry standards and guarantees production safety

- Conclusion

EN

EN