One of the most significant decisions you will have to make in your material handling system is the one of a bucket elevator; it all depends on the physical properties of your bulk material: is it fine powder or a granular material? Despite the fact that the fundamental idea with taking the material up and down in a row of buckets is the same, the design requirements and operation requirements differ tremendously. We have over three decades of experience in supplying high-performance machinery to our clients around the globe, At Shanghai Yuanyuda International Trade Co., Ltd., this is why we recognize that an incorrect configuration selection can lead to inefficiencies, product deterioration, and even system breakdowns. This document serves as a manual outlining the key variations between bucket elevators optimized for powder materials and those designed for granular materials.

Primary Design Focus: Containment vs. Flow

Powder Materials: Containment and dust control is the highest priority issue in the case. Fine powders will tend to aerate, fluidize and form dust clouds.Common types of powder elevators include continuous bucket elevators and enclosed centrifugal discharge types; buckets are closely spaced with little gaps to prevent leakage. They are enclosed in casings with tight fitting lids to allow a dust tight enclosure then typically sealed with special gaskets and airlocks inlets/outlets to ensure that pressure differentials will not blow out dust.

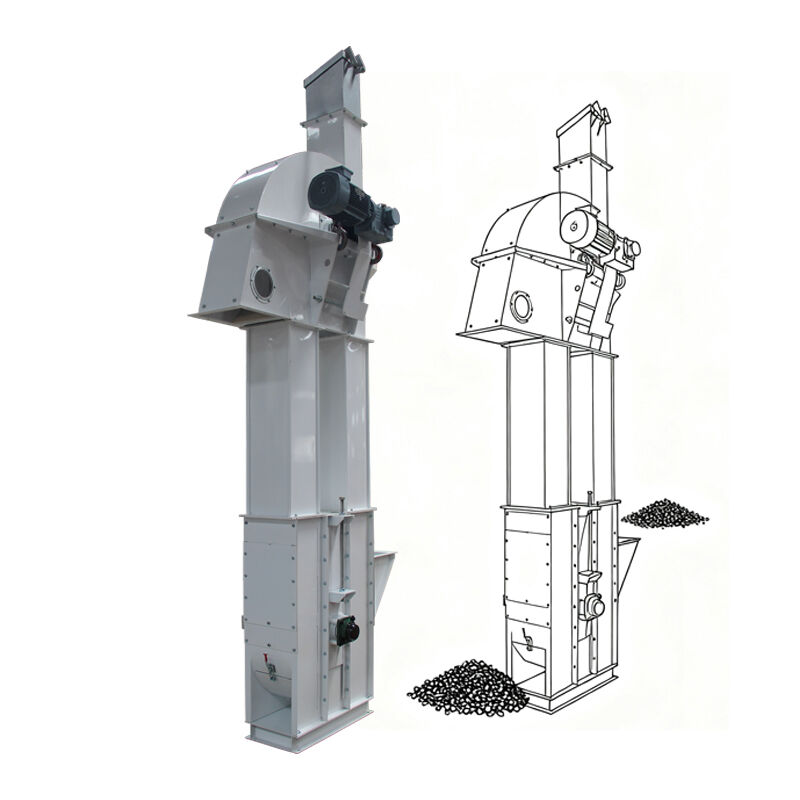

The main issue in the case of Granular Materials: The main issue is the effective clean discharge and pick up. Pellets (e.g., grains, fertilizers, etc.) are not as dusty and are free flowing. Centrifugal discharge bucket elevators are the most common ones. Here, there will be increased separation between the buckets and the design will use centrifugal force in the head pulley to hurl the material into the discharge chute. The casing is ventilated and does not require the same high level of hermetic sealing as that of powder systems.

Bucket Shape and Spacing

Powder Buckets: This is usually done by continuous buckets that are spaced close together and can be deep and narrow. Their design aims to minimize back-leakage, where the contents of rising buckets leak into the falling leg. In addition, buckets with overlapping sides are used to form an almost continuous line of containers, ensuring no material is trapped between them.

Granular Buckets: Buckets of this kind will be spaced (e.g. AA or CC style) and will often be wider and not so deep. This spacing allows granules to flow freely into the buckets during loading at the boot and enables complete, clean centrifugal discharge at the head section without bucket interference.

Loading and Discharge Mechanics

Powder Loading:Powder elevators can use induction loading, where material is loaded into upward buckets in a controlled manner to prevent excessive air entrapment and dust generation.The more common method is gravity discharge, where buckets are inverted at the head to ensure that the contents drop out of the buckets slowly due to gravity and that product degradation and dust generation are reduced.

Granular Loading: This is centrifugal or scoop loading, in the section of the boot where the bucket that are in motion scoop up the freely-flowing material. The most common method is centrifugal discharge, where the operating speed is high enough to hurl granules off the buckets as the buckets pass around the head pulley, achieving a positive discharge.

Operational Speed and Capacity

Powder Elevators: They are more likely to operate at lower belt or chain speed. High speeds can cause fluidization of the powder, leading to dust-related issues and an inability to fill the buckets effectively. It achieves the ability through the close placement of buckets rather than a high-speed placement.

Granular Elevators: This type of elevators is quicker in operation in order to cause centrifugal force that is required to discharge. Increased operating speed, combined with bucket size and spacing, is a key factor in boosting the elevator's capacity.

Construction and Sealing

Powder Systems: Requires sealing up. Casings are of heavier gauge and access doors are dust tight gasketed, and inspection panels are closed. Bearing and shaft seals are installed externally to prevent the ingress of powder, a problem that can easily cause rapid wear and component failure.Granular Systems: These systems are robust and only need to meet less stringent sealing requirements. Ventilation panels or dust vents are the typical way of equalizing pressure. The design prioritizes abrasion resistance at the loading and discharge points, where granules cause abrasion.

Special Considerations

Powder Hazards: There is explosive powder. Such materials must be handled by elevators equipped with explosion relief structures, anti-static features, and specialized electrical components compliant with standards such as ATEX.This is among the necessary directions where our knowledge and approved equipment (ISO, CE, SGS) will bring our foreign customers the assurance and conformity.

Granular Abrasion and Degradation: Hard angular granules are extremely abrasive. Abrasion resistant steel or coating may be required on buckets and liners. When handling fragile granules (such as certain fertilizers), gravity discharge is achieved with a gentle, low drop height to prevent breakage.

Choosing the Right Partner

Choosing between powder-grade and granular-grade bucket elevators is not a matter of simple modification.It requires precise engineering based on material characteristics like bulk density, particle size, flowability, abrasiveness, and explosivity.

At Shanghai Yuanyuda International Trade Co., Ltd., we leverage our 30 years of experience to provide customized turnkey solutions. From initial design and material analysis to the installation of the optimal system, we ensure your bucket elevator—whether for delicate carbon black powder or durable animal feed granules—delivers maximum efficiency, reliability, and cleanliness.Our certified (ISO, CE, SGS) equipment is trusted by clients in over 50 countries for advanced performance in feed, fertilizer, and new energy sectors.

Contact us today for a consultation. Let our expertise guide you to the perfect vertical handling solution that protects your product and boosts your productivity.

EN

EN