Main features

The body consists of a double screw belt and a top spray system. Packing seal is adopted at both ends of the shaft to improve the sealing and prevent the leakage of material at both ends of the shaft.

Double spiral belt structure with opposite rotation, no mixing dead angle, good mixing uniformity.

Special design of the door opening structure, large opening angle, rapid discharge of materials, less residue.

Good sealing, ensure no material leakage.

Adopting air door opening, accurate and reliable movement, good sealing.

The machine is equipped with grease adding pipeline, reasonable overall structure, beautiful appearance, convenient operation and maintenance.

Product description:

SLHY Screw mixer is applicable for the mixing of powder materials in the compound feed mill, making all feed compositions be homogenized and ensuring the quality of compound feed.

Features:

SLHY Screw mixer is a horizontal batch mixer. It has novel rotor structure without mixing dead corner, resulting in good mixing homogeneity. The gap between rotor and housing is adjustable. The materials are discharged along the full width of bottom, resulting in less remainder. Filler sealing avoids the materials leakage at two shaft ends. The discharging door is pneumatic (also can be electric) and motion is more accurate and reliable with good tightness. The machine is fitted with oil adding pipes. The machine has reasonable structure, fine appearance and convenient operation and maintenance.

Model information:

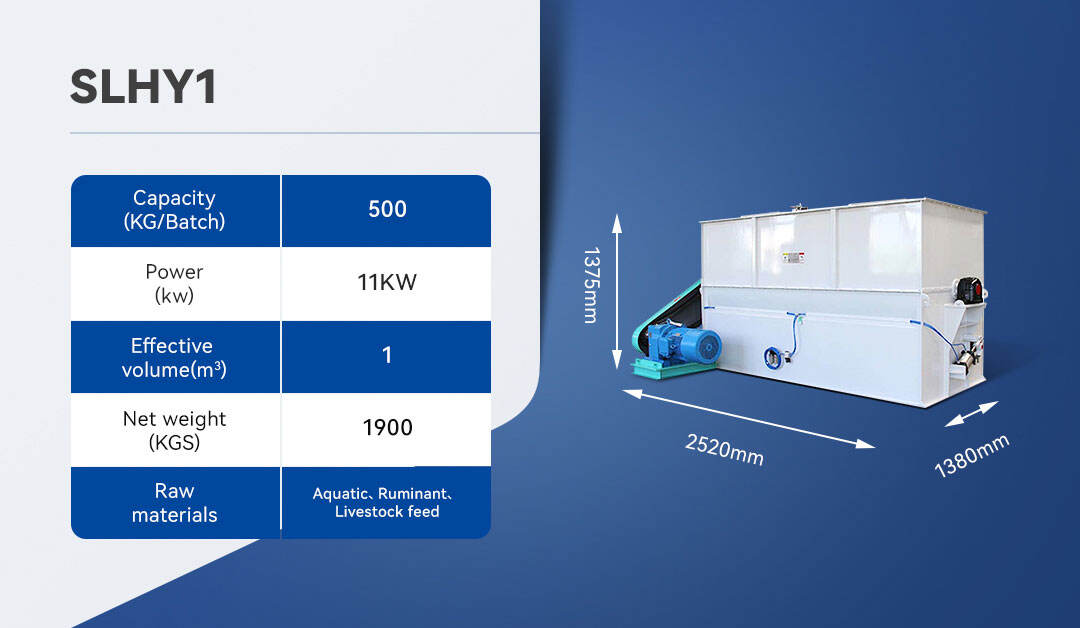

| Model | Effective volume(M3) | Power(KW) | Capacity(T/Batch) | Rotate speed(RPM) | Dimensions(MM) | Weight(KG) |

| SLHY0.6 | 0.6 | 5.5 | 0.25 | 31 | 2400*1190*1173 | 1150 |

| SLHY1 | 1 | 11 | 0.5 | 31 | 2520*1380*1375 | 1900 |

| SLHY2.5 | 2.5 | 18.5 | 1 | 34 | 3220*1890*1724 | 2790 |

| SLHY5 | 5 | 30 | 2 | 25 | 4090*2132*2072 | 3500 |

| SLHY7.5 | 7.5 | 37 | 3 | 25 | 5530*2080*2650 | 8000 |